Xeikon has developed a number of technologies and systems intended to advance the position of sustainable digital production of labels and packaging.

Brand-new are the Eco toner and quality measurement module (QMM). Whilst Eco has been formulated with over 60% high-grade recycled PET – ‘making it the ideal solution for environmentally conscious packaging applications’ – QMM is responsible for the quality assurance of the printed output, closely monitoring the density and registration throughout the print run. This is noted by the company as helping to eliminate waste and ‘guarantee high quality’, which is said to support the advancement of sustainability in digital label production. Both are part of the company’s new Cheetah 3.0 platform.

Also new is sustainability scorecard, which offers a more transparent means of proving compliance with various regulations and aids brand owners with their sustainability goals. The scorecard will analyse and illustrate the carbon footprint of each Xeikon press, right down to the individual components of the consumables. It will identify food compliance, VOCs emissions, recyclability and energy use to give a complete overview.

Xeikon Panther series presses running the company’s PantherCure LED inks are given as an example, with the company’s sustainability scorecard highlighting their claimed reduced carbon footprint credentials.

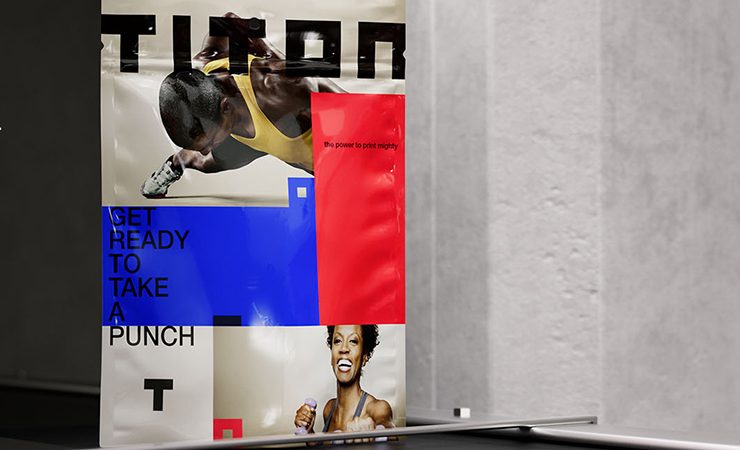

These will both be introduced at Labelexpo Europe 2023, where the company’s Titon toner technology will have its European premiere. Titon has been developed to meet market demands for paper-based flexible packaging applications, such as stand-up pouches and sachets. The first press presented with Tition technology is the 520mm-wide TX-500, which prints in up to five colours at 30m/min and a resolution of 1200dpi.

Xeikon will be showing TX-500 running live inline with a digital embellishment module from Kurz, producing full-colour, high-end labels with digital foil.