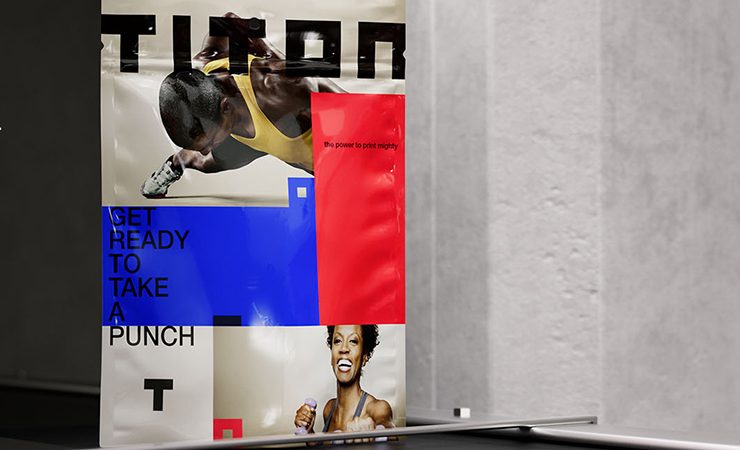

Xeikon has introduced Titon, a new toner formulation responding to sustainability trends in packaging, and claimed to offer, ‘all the benefits of UV inks without the disadvantages.’

Specifically, Titon can be used to print many types of flexible packaging for food products, including papers that are coated on one side for bags, pouches and sachets, or on both sides for wrappers such as baked goods, confectionery, sugar, flour, herbs and spices, and coffee and tea.

As brand owners continue to convert film-based packaging to paper, Xeikon noted that allowing the move to recyclable paper-based packaging puts Titon technology in a, ‘ground-breaking position in the digital printing landscape, and it gives printers the opportunity to expand their capabilities into applications that could not previously be addressed with digital, complementing their conventional flexo presses.’

Frank Jacobs, market intelligence and senior product manager at Xeikon, commented, ‘The flexible packaging market is moving towards more sustainable paper-based solutions in response to strong consumer demand for plastic-free alternatives. With the new Titon technology, Xeikon is offering a sustainable solution for an unexplored and wider variety of applications to fully support brand owners, designers and printers wishing to increase their use of paper-based packaging for food products.’

Titon builds on the core value of Xeikon’s dry toner technology which, due to the absence of any liquid (mobile) components, is said to be the most food-safe digital printing technology available in the market, even with only paper as the main functional barrier. Titon is also completely odourless and tasteless. Such characteristics make this technology suitable for a broad range of applications with indirect and direct food contact.

Mr Jacobs continued, ‘With the migration towards paper-based packaging printing, the demand on the print technology has become more stringent in terms of being food safe without a plastic functional barrier or plastic lamination to protect the print itself.’

Titon toners also offer resistance to scuffing and scratching, water, sunlight, high temperatures and a large set of liquid chemicals, without the need varnishing or lamination. Being able to print directly on paper substrates without varnishing or lamination, either inline or offline, has a significant impact on overall equipment effectiveness (OEE) of the digital printing operation. Further, Titon toners can withstand heat sealing temperatures of up to 220-260 degrees C (428-500 degrees F).

The first digital press model to run Titon technology will be the new Xeikon CX500t Cheetah digital press. Adding the extra capabilities of Titon to the successful 510mm-wide machine allows converters to broaden their reach and enter new market segments.

Mr Jacobs said, ‘Once again, Xeikon is paving the way for converters to future-proof their business by developing solutions that help them stay ahead of the curve and respond to market needs for high quality, sustainable and cost-effective solutions. It reaffirms our dedication to the labels and packaging market and is the perfect illustration that application-tuned products are key to driving growth.

‘The ground-breaking Titon toner brings new market opportunities for digital print that no other digital technology can offer, and it will set a new standard in flexible packaging production.’