Sticker Gizmo, based in Redditch, UK, has invested in a Xeikon 3030 REX factory refurbished digital label press.

School Stickers specialises in printed school rewards products, selling both printed rewards and software. It developed software to link physical printed rewards to an online experience. Sticker Gizmo is a B2B sister company of School Stickers, facilitating expansion into new markets.

Alistair Tillen, executive chairman at the Redditch-based business, said, ‘Quite quickly it became apparent we needed to expand our printing capabilities so that we could compete on larger orders. We embarked on a period of research where we looked at several different options including outsourcing. In the end we decided it was important to own the whole customer experience and be solely responsible for quality and delivery times.’

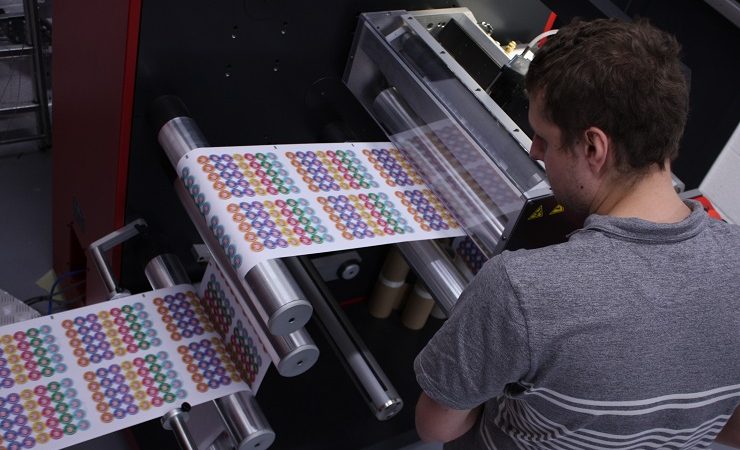

The Xeikon 3030 REX can print on substate widths of up to 330mm and can print at up to 9.6m/min at a 1200dpi resolution. That equates up to 190sqm an hour. The system images using environmentally friendly dry toner, which is water resistant and has a high light-fastness for outdoor work. The system prints on standard substrates with no need for pre-coating. Sticker Gizmo is keen to offer recycled substrates to its customers and offers these at a lower price to regular materials on its website, even though they cost the company more to purchase from the supplier.

The Xeikon represents a significant upgrade for the organisation, which had previously relied on other toner-based printers and cut-sheet labels for its output.

Mr Tillen continued, ‘We were keen to invest in a machine that would help us expand and keep pace with our aggressive growth plans. A Xeikon machine was always near the top of our list but when we found out about the factory refurbished REX machines, we knew we had found the right solution for us.’

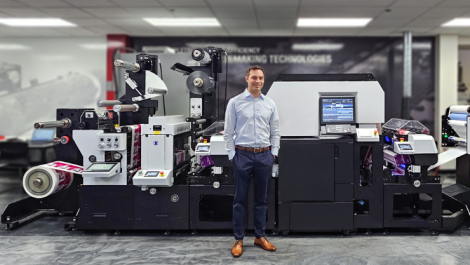

Xeikon introduced REX earlier this year as an initiative to support printers looking for entry-level, affordable digital production options. Duncan Sargeant, Xeikon UK sales manager, commented, ‘Used for demo or sold to the commercial market by Xeikon, these presses have been supported by Xeikon engineers, who know the ins and outs of the press regarding it’s age, usage, and service history. Every press considered for the REX program goes through a detailed technical ‘condition scoring’ examination.

‘Our factory engineers then replace and optimize every critical component required for an extended life for the press with perfect print quality. Every Xeikon REX digital press has been updated to the latest revision of both hardware and software, making it ready for years of production. Then, only after going through extensive testing, is the product boxed and shipped to the customer.’

The Xeikon 3030 REX was installed in August and is already beginning to change the business for the better, according to Mr Tillen. ‘We are already seeing the benefits of the Xeikon machine with improved productivity helping us cut delivery times to our customers. We are also delighted with the print quality and have started to benefit from lower substrate prices as we move away from pre-cut sheets.’

Speed and width upgrades are already being considered.

Mr Tillen said, ‘The company believes the combination of its software pedigree and the improved print execution that the Xeikon provides is an excellent platform for growth.

‘We have a number of new developments in progress including an update to our online design tool to make it easier for users to create their own library of label designs, along with our digital label service which uses the same technology we developed for the schools’ market to link labels with an online experience.’