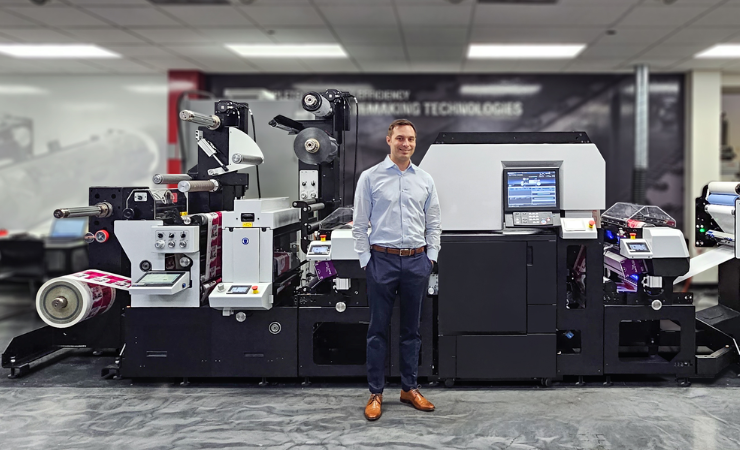

Mark Andy has launched a new version of its Digital Pro series of hybrid presses, with the new Plus model aimed at medium-run, high-quality digital jobs that are produced using a combination of dry toner with optional flexo and inline finishing.

Digital Pro Plus (DPro Plus) is built on the Mark Andy Pro Series flexo platform bundled with a toner- based digital engine. It offers a standard web width of 330mm, four-colour digital printing and a 1200 x 2400dpi print resolution, equivalent to 3600dpi. Production speeds up to 24m/min are achievable on a variety of substrates, ranging from paper to supported films and foil. A variety of inline converting and finishing options complement the CMYK dry toner process, such as flexo printing before and after the digital unit, cold foil, lamination, semi-rotary die-cutting, slitting, scoring, sheeting and delivery.

With no ‘clean room’ requirement, DPro Plus can be used to produce a variety of prime pressure-sensitive labels for the food and beverage, industrial, craft goods and health and beauty sectors, amongst others. Variable data capability suits the reported increasing demand for shorter runs, more personalisation and versioning, as sought by brand owners and print buyers alike. A compact footprint means Digital Pro Plus can fit into ‘the most crowded production floor’.

Digital Pro Plus is described as, ‘An affordable and versatile digital hybrid with expandable capabilities to suit changes in market demand, from roll-to-roll to a fully configured single-pass print and finishing line,’ as said Mark Andy’s product manager for digital presses, Ben Luly.

‘We genuinely see it as a clear roadmap for growth as its capability can be scaled up as and when required. It’s the right press for high-quality CMYK printing roll-to-roll but is easily and affordably upgradeable to a full-scale inline production tool that can include flexo printing before and after the digital unit, cold foil, lamination, semi-rotary die-cutting, slitting, scoring, sheeting, and delivery onto a stack conveyor; it really is a great all-rounder.’