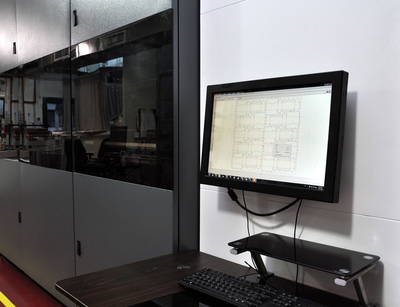

Esko and Highcon, have reached an agreement that will see Esko CAD Digital Front End (DFE) software complement the Highcon Euclid digital cutting and creasing machine.

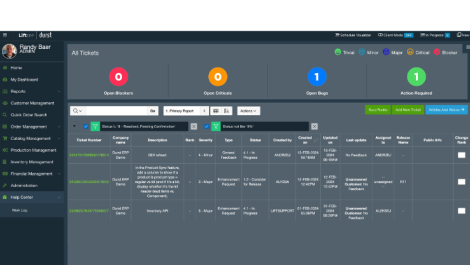

With the new OEM agreement, the Euclid now offers an on-board software tool, the Highcon Light Editor, that allows operators to take full advantage of the benefits of digital technology by editing crease and cut lines in the structural design of the job at the point of production, including the ability to incorporate last-minute changes. It also enables the use of nicks by increasing or decreasing their size, and allows adding removing or editing stripping lines.

‘We are proud of the opportunity to partner with Esko, incorporating their industry-leading technology into our game-changing digital converting solution,’ commented Eitan Varon, Highcon’s executive vice president. ‘We have been working with Esko since the beginning and are excited to extend this collaboration for the benefit of our existing and future customers. Flexibility is one of the key advantages of digital technology and by implementing the Esko CAD DFE, our customers will be able to perform a wide range of last minute edits that ensure the proper production of the package, promotional item, or greeting card that their clients require.’

‘This late-stage capability is especially important in an environment where run lengths and cycle times are compressed,’ added Richard Deroo, product manager structural design at Esko. ‘Packaging converters accept files from a wide variety of sources, and it is essential that they have the ability to control final structures at the point of production to ensure a consistent quality product with limited waste and downtime.’

‘Esko’s mission is to deliver integrated customer solutions that drive profitability throughout the printing and packaging supply chain,’ concluded Mr Deroo. ‘By partnering with Highcon to integrate Esko’s CAD DFE with the Highcon Euclid, the packaging workflow is streamlined through the ability to perform edits to design files at the point of production, ensuring optimal digital converting in the fast-paced world of digital packaging production. This minimizes downtime and maximizes productivity. We are very pleased to be working with Highcon to bring this innovative solution to the market.’