Here, we report on the digital label printing technologies that have been and continue to be developed for the next stage of digital package printing and converting.

Labels were one of the early markets to see the value in digital printing, and as such it is now one of the most mature markets for the technology.

While not this segment of the packaging market’s big event, drupa does provide a platform for and necessitate suppliers to the label market to bring forth new technologies.

Take Xeikon’s new CX300 as an example. It replaces the CX3, which was debuted at Labelexpo Europe 2015, and provides an upgrade path to the CX500. CX300 is a 330mm-wide label press that can offer production capacity of over 50,000sqm a month in single-shift operation. The full-colour press is equipped with five print stations, including CMYK and single-pass opaque white, but can also support colour gamut expansion, custom or security colours. It is based on the company’s Cheetah 2.0 technology, itself based on the proven, scalable Xeikon press architecture that includes five print stations and a full rotary process with a variable repeat length. Other features include: a printing speed up to 30m/min; a printing width of 220-512mm; an LED imaging head operating at 1200 x 3600dpi and delivering image quality comparable to offset and gravure; and the Cheetah developer station that ensures a higher colour consistency across and along the web. A new man-to-machine interface has been designed in a way that the operator can assess the status of the press from a distance; the interface also communicates the specific actions the operator needs to perform. A machine-to-machine interface allows for the integration of pre- and post-printing equipment, either inline or offline.

The HP Indigo 6K and 8K similarly update existing digital label printing technology, the 6900 and 8000 models respectively. The HP Indigo 6K digital press has been engineered to deliver more applications using higher opacity white for shrink sleeves, new inks including silver, fluorescents, invisible red and green for brand protection applications, and new varnishes from industry partners that offer enhanced mechanical durability and improve the characteristics of those labels produced using the Pack Ready for Labels ecosystem. Similar additions have been made to the new and improved 8000 digital press, including increased productivity, reduced waste, and easier transitioning between media types and jobs.

V12 has also been announced by HP Indigo. While ‘K’ presses are part of its Series 5 portfolio, V12 is its first Series 6 press and not scheduled to be commercially available until 2022. V12 runs an entirely new digital printing platform based on LEP, LEPx. It also uses an inline print architecture as opposed to the usual central impression (CI) design within HP Indigo digital presses, with a blanket belt allowing up to 12 colours to be printed at 1600dpi at a width of 340mm, and with a 5.33m repeat length. Six print stations, each with a writing head and two BID (binary ink developer) units, equates to the 12 colours. This requires the blanket belt to rotate twice for 12 colours to be laid down, and results in a speed of 60m/min (200ft/min). When only six colours are used, and a single rotation of the blanket belt is required, a maximum print speed of 120m/min (400ft/min) can be achieved. A 1600dpi resolution means HD capability, suitable for security printing and small fonts.

Canon has upgraded its LabelStream 4000 Series, adding an optional orange colour channel, a screen-like high-opacity white ink, and enhanced usability for greater production efficiencies. The new white ink channel achieves up to 80% opacity at 36m/min in a single pass. The LabelStream 4000 Core unit provides an entry-level option that can be expanded to meet specific requirements. A Hybrid configuration offers a custom mix of UV flexo, embellishment and finishing units.

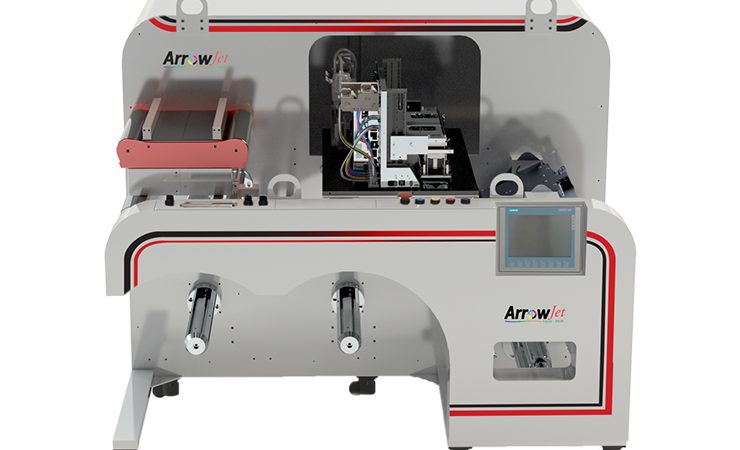

Arrow Systems with ArrowJet Aqua 330R, Printing Innovation and the second-generation iCube X000, and Colordyne with its ChromaPlex print engines have innovated with inkjet. At Colordyne, this has seen it create a new business unit targeted at strategic integration partners (SIPs) interested in adding inkjet technology to their products. These new systems are each built on Memjet technology, with a number of others doing likewise as Memjet continues to advance its technology.

Read about the latest technological developments in digital flexible package printing here

Read about the latest technological developments in digital folding carton printing here

Read about the latest technological developments in digital corrugated printing here

Read about the latest technological developments in finishing and converting here