The ability to add variable data to labels and packaging has become one of the most meaningful advantages of digital printing. Whether it’s serialisation, batch information, personalisation or limited-edition branding.

As product ranges, formulations and compliance requirements continue to evolve, manufacturers are under increasing pressure to maintain flexibility and adapt quickly within fast-moving production environments. Modern operations often require the ability to switch seamlessly between batches, product variations and regulatory demands without slowing production. This variable data can include expiry or best-before dates, serial numbers, batch codes, barcodes, or even promotional QR codes.

Accurate and legible variable data printing is essential for compliance, traceability, and consumer confidence. Thermal Transfer Overprint (TTO) technology has become a preferred digital printing solution for adding variable information – such as expiry dates, batch numbers, barcodes, and 2D codes – directly onto packaging and labels during the production process.

TTO delivers high-resolution prints with excellent contrast and readability, ensuring codes remain clear and durable throughout the product lifecycle. Unlike other coding technologies that slow down when printing large or complex codes, TTO maintains consistent line speed regardless of code size. This makes it ideal for applications requiring detailed information, such as pharmaceutical, medical device, and food packaging.

Designed for seamless integration into form-fill-seal machines, TTO printers work across a wide range of substrates, including flexible packaging films, non-woven materials like Tyvek, and labels. This versatility enables manufacturers to meet diverse packaging requirements without compromising speed or quality.

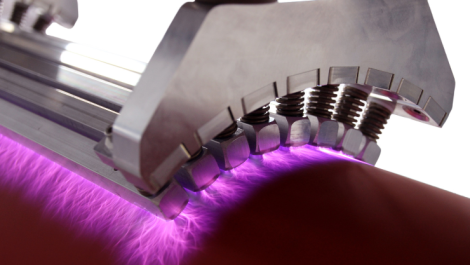

The process is simple yet highly effective. A ribbon coated with ink passes beneath a heated printhead, which melts the ink and transfers it directly onto the packaging substrate. The ink cools almost instantly, creating a durable, high-resolution code that withstands handling and environmental conditions. This supports precision and reliability, even at high speeds.

Where other technologies struggle with multiple lines or complex codes, TTO excels. Its performance is unaffected by code size, making it the perfect choice for manufacturers who need to print expiry dates, batch numbers, and GS1 compliant machine readable codes without sacrificing throughput.

These capabilities help minimise maintenance, reduce errors, cut cost, and waste – while maximising overall equipment effectiveness (OEE) and supporting sustainability goals.

TTO printers are widely used in sectors where speed and accuracy are paramount. In pharmaceuticals and medical devices, they ensure regulatory information is clearly printed on sterile packaging. In the food industry, they provide essential details like best-before dates and batch codes, helping maintain safety and quality standards.

A different way

As an alternative to TTO, thermal inkjet printing (TIJ) is a straightforward, low-maintenance solution that can help manufacturers to reduce waste as well as costs. Rather than using a ribbon, TIJ printing is a non-contact printing method; the ink in the print cartridge is heated by tiny resistors that produce vapour bubbles that eject droplets on demand.

AM Labels has recently added the M2 Thermal Inkjet Printer to its portfolio, a versatile unit programmed via a touchscreen controller and supported by USB data transfer. Easy to operate and set up, the M2 integrates directly into production lines to deliver accurate variable data at speed. The M2 runs HP print cartridges and can use one or two heads, which can achieve up to 600 x 600dpi.

Importantly, each ink cartridge includes its own built-in printhead. This keeps the cost of ownership low by eliminating expensive printhead replacements and reducing the need for service engineer intervention.

The ink cartridge is combined with the printhead, ensuring consistent print quality is maintained as well as reducing maintenance demands. With two printheads available, the M2 can also apply data from different angles or at multiple stages of the production flow, offering essential flexibility without additional hardware cost.

The ink cartridge is combined with the printhead, ensuring consistent print quality is maintained as well as reducing maintenance demands. With two printheads available, the M2 can also apply data from different angles or at multiple stages of the production flow, offering essential flexibility without additional hardware cost.

Once the ink cartridge is depleted, you simply replace it and continue production. In highly variable environments, this printing method can offer great value and exceptional flexibility. It also produces less waste than ribbon-based printing. Additionally, the M2 can automatically monitor ink consumption, giving manufacturers clear insight into usage levels and helping optimise operational efficiency.

With its combination of reliability, low maintenance, and the ability to print high-quality variable data on demand, the M2 Thermal Inkjet Printer helps manufacturers stay agile and efficient in fast-paced production environments. By reducing downtime, simplifying maintenance, and providing precise control over ink usage, it delivers both operational flexibility and cost-effective performance, while reducing material waste too. It is an ideal solution for companies looking to keep production moving while meeting the demands of modern packaging and labelling requirements.

Pressing the advantage

Variable data allows converters and brand owners to respond quickly to market needs and deliver the kind of targeted, premium packaging today’s customers expect. But unlocking this capability in a cost-effective way has historically been a challenge – especially when it comes to metallic or decorative finishing.

Traditional hot-foil stamping still produces beautiful results, but it is inherently inflexible. Every new design requires a die, every small run becomes expensive, and setup time can slow down production to a crawl. For many printers, this means using metallic effects only when volumes are high enough to justify the upfront investment. When variable data enters the equation, hot stamping becomes even less feasible.

This is where digital foil imprinting fills an essential gap. DTM Print’s FX810e and FX510e Foil Imprinters demonstrate how digital finishing can deliver both creative impact and operational efficiency.

By eliminating tooling expenses entirely these devices turn short-run or highly personalised jobs into profitable ones. For brands increasingly focused on limited editions, seasonal variations or personalised packaging campaigns, this agility is invaluable.

Beyond their flexibility, the FX810e and FX510e are engineered to keep the total cost of ownership low. Both printers achieve speeds of 101.6 mm/per second, supporting efficient production without sacrificing decorative quality. Each uses DTM Print certified thermal-transfer ribbons, with metallic foils available in gold, silver, blue and red, alongside various spot colours and clear foil. Clear foil makes it possible to produce labels with partial glossy enhancements, ideal for logos or graphical highlights. Four 100-mm metallic ribbons in gold, silver, red and blue are included, allowing users to start creating standout designs immediately.

Cost-efficiency extends far beyond setup. DTM Print’s foil systems optimise ribbon usage, allowing printers to match ribbon width to the artwork instead of wasting material on non-printed areas. The result is a lower cost per label, even for metallic or specialty finishes. On-demand production further reduces waste by ensuring that only the quantity required is produced.

The FX810e and FX510e are also designed with day-to-day practicality in mind. With low energy consumption, robust construction and minimal maintenance needs, printers can integrate them seamlessly into existing workflows. Included software simplifies operation and enables users to begin printing variable data quickly. Both models also come with a passive label unwinder that accommodates larger roll diameters – an advantage for higher-volume or continuous workflows.

What makes this technology particularly compelling is how it brings premium finishing within reach for smaller companies such as boutique label printers, artisanal brands and craft producers, who may previously have avoided foil embellishment due to cost. By providing a digital alternative that combines creative freedom with operational efficiency, DTM Print has democratised access to high-value decoration that elevates both brand perception and shelf appeal.

Variable data may be one of digital printing’s greatest strengths, but it reaches its fullest expression when paired with the ability to personalise not just information but aesthetics. With the FX810e and FX510e, DTM Print offers printers a way to do exactly that: add beauty, flexibility and profitability to their workflows – all while keeping the total cost of ownership firmly under control.

Thermal Transfer Overprinting technology combines speed, flexibility, and precision, making it a go-to solution for variable data printing on packaging. Its ability to handle large, complex codes without slowing production sets it apart from other technologies, ensuring manufacturers can meet today’s demanding requirements with confidence.

Pairing this technology with the right partner helps ensure your production line runs smoothly, efficiently, and error-free.