Phil Baldwin, Sales Manager at Mark Andy UK looks at digital printing options in the converting sector and explains how you can enjoy the best of both technologies.

So, you’ve decided to go digital for your next narrow web press but you’re unsure which of the two types of technology, inkjet, or toner, to choose. It’s a common question we are asked and an important choice for you to get right – but as with most investment plans, it’s never quite that straightforward.

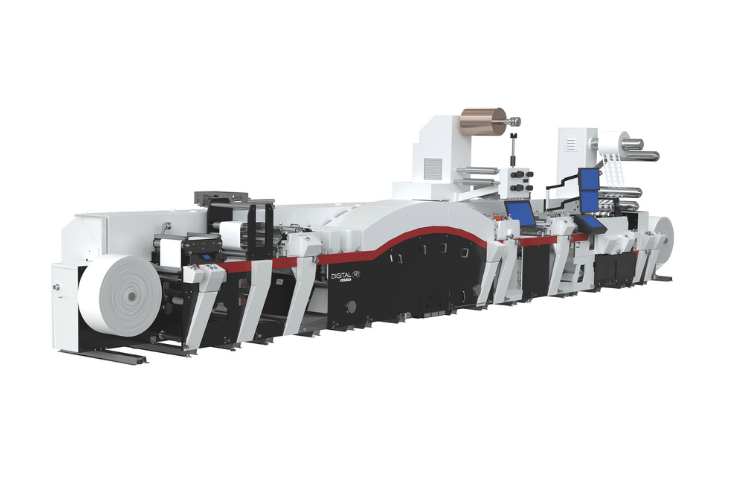

Digital Pro Plus r2r – for roll-to-roll applications

As the label sector comes under increasing pressure to produce shorter runs with an increasing number of SKUs, converters that traditionally have used flexo presses are forced into choosing between outsourcing the jobs that are no longer economically viable to handle in-house, or look at investing in a digital press, which can be a daunting prospect first time around, with differing technology and a large number of potential manufacturers to choose from.

Or, converters can look at what we at Mark Andy have to offer, which will provide them with a solution that will meet their current requirements and be up-scalable as their business grows and demand changes. And, the upside of this is that it can all be done with well-proven technology that is familiar an easily assimilated into existing production capacity.

Essentially, what we’re discussing here is a ‘hybrid’, which can be a combination of toner and flexo or inkjet and flexo – the choice of which will largely be determined by the type of work being undertaken. So, what are the options and how do you know which way to go? The best way of explaining is to look at the digital options in our range of hybrid presses.

Digital Pro Series

Our current version, the Digital Pro Plus, builds on the success of the Digital One that was launched in 2016 and enjoyed more than 125 sales in Europe and the US markets. Digital Pro Plus sees the addition of Mark Andy’s latest Pro Series flexo stations and increased converting and finishing options, making it an ideal first digital press for short to medium run work.

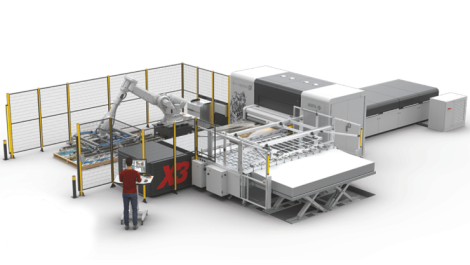

The very latest addition to the Digital Pro range is Digital Pro MAX, which offers an even broader range of configuration options to suit specific requirements and the ability to add features as business grows. This makes it ideal for larger volume work because it releases capacity on flexo presses. It offers CMYK plus toner white, with end-to-end print and converting at speeds up to 40m/min. Its modular platform allows the converter to specify the press to meet current requirements and the upgrade later as demand changes. Converting options include cold foil, laminating, and turn bars for reverse side printing, along with semi-rotary die cutting.

Digital Series HD – for high-end sophisticated labels

We see the DPro MAX as a perfect fit for the legacy flexo press sector where short runs are the norm and the shortage of skilled flexo operators is a growing problem. Instead of a ‘click charge’ DPro MAX has a ‘pay as you print’ system, which is one of the keys to its low-cost operation that allows converters to maximise production efficiency. This method offers a significant benefit over other suppliers tied to a set price click charge, regardless of job design and coverage.

Digital Series iQ

In the medium run sector, the Mark Andy Digital Series iQ is a cooperative venture with Domino, which supplies the UV/ inkjet engine installed on an Evolution flexo platform. Mark Andy has the most advanced integration of the Domino engine into a hybrid configuration, and DSiQ can be configured with up to seven UV inkjet colours (CMYKOV +WW), with converting components integrated to meet each customer’s specific requirements. Print stations, semi rotary vertical die cutting, cold foil, and inline slitting are common options. The press is capable of speeds up to 70m/min in rapid production mode, while the dual white print bar design offers screen-like print effects and can create a raised embossed-like image or text. The Domino engine prints with a 600dpi resolution.

The system has automated print head cleaning and capping as well as ink recirculation. Significant for those converters involved in food packaging the DSiQ can be specified to run Domino’s UV95-V2 Series inks that are suitable for non-direct food contact packaging applications. The inks are manufactured in accordance with current EuPIA Good Manufacturing Practices, and the exclusion criteria defined in the EuPIA Guideline on Printing Inks applied to the non food contact surface of food packaging materials and articles.

Digital Series iQ-R

Going hybrid has never been so easy as with the new DSiQ-R unit that is designed to be retro-fitted to any Mark Andy Evolution and Performance Series flexo press. With many new software enhancements, it offers VDP along with barcoding, and fine print with screen-like white, all in a single pass, and its user interface integrates seamlessly with existing Mark Andy control panels. If you’re looking to add flexibility and more cost-effective production to your flexo presses, DSiQ-R is a great option.

Digital Series HD

At the top end of the Mark Andy hybrid range is the Digital Series HD. This line is unique because it is the only fully in-house developed and manufactured hybrid press on the market and has by far the highest number of customer installations worldwide. DSHD is targeted at the premium label sector where added value combined with the highest quality resolution is essential to brand owners. With hardware and software developed to work seamlessly, the DSHD can be configured with up to eight UV/inkjet colours (CMYKOGV+W) and operate at 73m/min without any sacrifice to its 1200dpi resolution.

Digital Pro MAX – for medium to longer run jobs

The DSHD is the most comprehensive hybrid on the market with almost limitless possibilities in the food & beverage, health & beauty, industrial, and speciality sectors. All the inks are Swiss Ordinance compliant, have extremely high rub scuff and blue wool scale ratings, and have been engineered for high performance and durability.

Built on the Performance Series flexo platform, DSHD has a substrate range from self-adhesive paper and film to tag stock and light cartonboard. The flexo stations can be used for spot colours, top coating, metallics, or cold foil and the line is completed by a QCDC semi-, or full-rotary die cut unit. Other options include lamination, hot foil, rotary screen, embossing, slitting, and scoring. Turn bars can be fitted for reverse side printing and delivery can be via a shingled conveyor. As a true single supplier hybrid DSHD is a future proof press with no risk of an OEM partnership fail.