Cartes, a global leader in label finishing machines, reports that a high percentage of its lines delivered in 2024 included one or more inkjet embellishing and laser converting units. Written by Lorenzo Villa.

Digital transformation in the label industry has grown more rapidly and incisively than other printing and packaging sectors. Compounded by the increased offer from narrow-web press manufacturers, several converters have confidently adopted digital printing technology, stand-alone or integrated into hybrid lines, over the past 15 years. This revolution began with the first liquid and dry toner printers more than two decades ago and has continued over the past decade with the skyrocketing inkjet technology.

Separate discussion deserves die-cutting, varnishing, and hot foiling, where the complexity of the process, combined with the variety of substrates, made the digital transition more complex and limited the number of players to a handful. Among them, Cartes is the only one to boast a deep analog cultural heritage and to distinguish itself as a pioneer, who’s been able to create and improve technologies that have inspired many and caused some debate.

A history of analog leadership, shaken by a digital faith

In 1999, Cartes became the first label machine manufacturer to venture into laser cutting technology, which was considered an aberration by most purists. Although best practices in label production suggested that only a mechanical die cut could guarantee the quality, cleanliness, and productivity demanded by converters, Cartes believed that the challenge was not impossible.

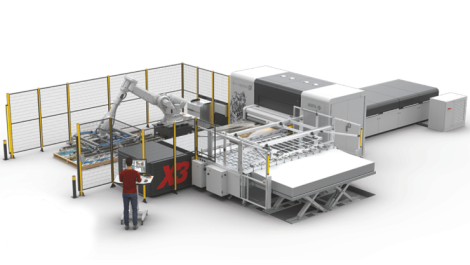

The Cartes GEMINI GE363VJL with Jet D-Screen

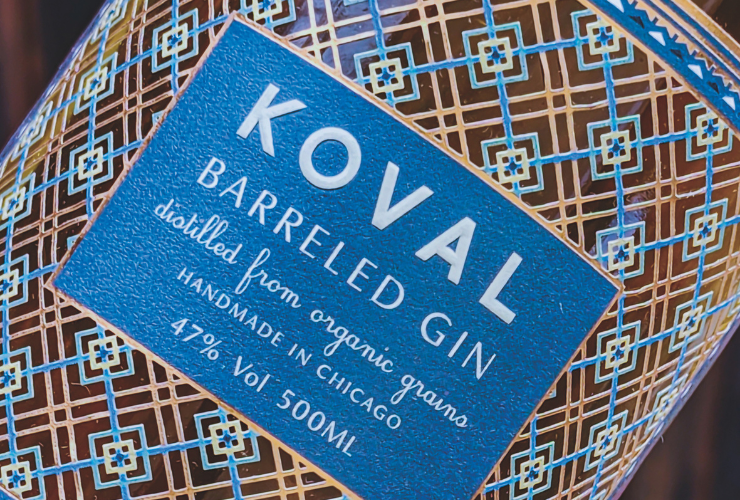

“In those years, even talking about flexible dies was unorthodox, and explaining the potential of laser cutting amounted to heresy,” says Mario Lodi, Cartes founder. “But many people trusted us, and today, some of our first laser machines are still fully functional, 25 years later.” Despite the predictable distrust of the market and the many critical issues to be solved, Cartes never stopped improving and perfecting the technology, to the point of clearing it as a de facto standard for the most demanding brand owners in the wine, spirits, perfumery and luxury goods segments.

From screen printing to digital embellishment

No less challenging than laser cutting was the path undertook by Cartes in 2019 in the field of digital embellishment. An undisputed leader in semi-rotary screen printing, with a solid reputation for the precision, reliability, and performance of its finishing machines, Cartes decided to take the inkjet route. Almost following a script, the manufacturer’s bold move attracted the distrust of the more orthodox operators, and the curiosity of the more enterprising. The research and development, conducted entirely in-house, was influenced by advances in the field of digital glazing achieved in the nearby ceramic district, that groups together the 80 percent of Italy’s ceramic tile production.

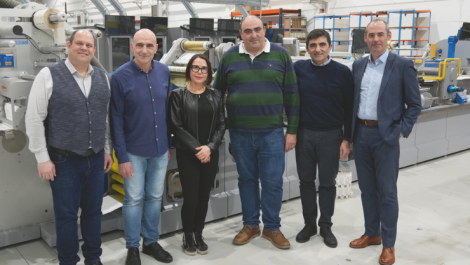

From left to right: Mr Carlo Stefano Lodi, Mrs Enrica Lodi, Mr Mario Lodi

from Cartes with the award won as best technological innovation of 2023

“We observed that the ceramic decoration needed to deposit high thicknesses of glaze to reproduce the grain of wood and the surface of stone,” explains Carlo Stefano Lodi, Cartes CEO. “Similarly, in label embellishment, optical and tactile effects are required to be thick enough to reproduce the effects of embossing and braille.”

In 2020, JET D-Screen (whose name is a homage to screen printing) was already up and running, and was conceived and proposed as an add-on module for the new and the existing Cartes finishing lines, often in combination with the foiling unit, to create metal doming effects. As we can observe, the JET D-Screen will soon become one of the most popular options within the bestselling GT360 and Gemini series units.

From option to must-have

Designed to minimize manual operations and the number of start-ups, Cartes lines may include units for flexo coating, screen printing, hot stamping, flat and semi-rotary die-cutting, multi-layer label application, cut-off windowing, and more. In recent years, such a modularity encouraged many converters to put up to a dozen Cartes machines side-by-side in different configurations, so that each line can be leveraged to make complex labels in one pass, never precluding upgrades and modifications. For many, laser die-cutting and JET D-Screen are an enabler to win new jobs and new customers in the short-run and just-in-time arena.

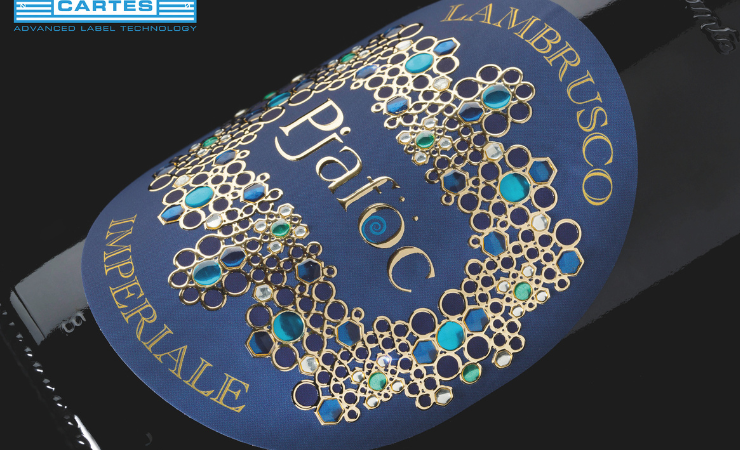

The winning label from the 2023 Leaf Awards made with Cartes Gemini

“Over the past four years, we observed a growing interest in laser die-cutting and digital screen printing among traditional label makers, online printers and newcomers,” says Enrica Lodi, Cartes’ chief marketing officer. “What seemed like a pioneering choice in 2020 is now the standard configuration, to the point that a high percentage of machines delivered in 2024 included a digital unit, and many users of already installed machines asked us to retrofit their lines with JET D-Screen.”

Converters who have chosen laser die-cutting and JET D-Screen, often combined with screen printing and semi-rotary die-cutting, include primary converters such as Spain’s Graficas Tomelloso (part of Labelys Group), Italy’s Multistampa, Imoco, and Sovemec, Portugal’s Etiquel, France’s LP2i, the US-based Paragon Label (part of Resource Label Group), and some large online printers, including Poland’s Labo Print.

Website: https://www.cartes.it/en/homepage/

This article is an advertorial; the featured company created the wording and paid for its placement. It has been checked by Whitmar Publications to ensure that it meets our editorial standards.