The collaboration between the Italian manufacturer and the Spanish converter, part of the Labelys Group, turns 14 and grows amid technological innovation and new installations

Established in 1995 in Tomelloso, in the autonomous community of Castilla-La Mancha, south of Madrid, Graficas Tomelloso initially focused on sheetfed printing, carried out with small letterpress machinery. The brothers Patricio and Ángel Morales founded the company and decided to focus on the lucrative label market, soon joined by their brother Julián. Aided by the region’s hot, dry climate, which favours the growth of full-bodied vines, the company focused on producing wine labels and, in the early 2000s, introduced offset and flexo presses to produce roll labels. In 2006, it also purchased an HP Indigo digital press to meet the growing need for small quantities and customised labels. In 2010 and meeting with Cartes marks a turning point for the company, successfully serving wineries throughout Spain and parts of France. Installing the first Cartes line, a GT360 with two screen printing, hot stamping and flatbed die-cutting units, was the beginning of a successful partnership, which will lead the company to purchase ten Cartes machines in just over a decade.

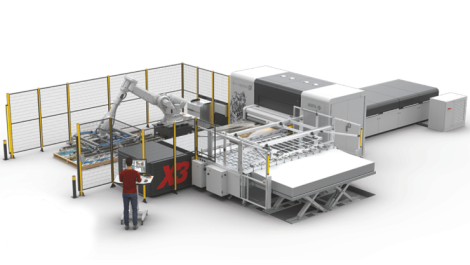

To boost its production capacity, and make even more unique and valuable products, in 2022 Graficas Tomelloso introduced a Cartes Gemini GE363 with dual Jet D-Screen digital embellishment units, and in June 2024, added the ninth GT360, equipped with flexo and screen printing units, and semi-rotary die cutting. With a turnover of about 6 million euros and 46 employees, since 2024 the Spanish company has been part of the Labelys Group, which joins 18 production sites in five European countries, with a total of 800 employees and more than 130 production lines installed. The production of wine labels close to production areas is one of Labelys’ cornerstones, along with labels for the industrial world and online label sales.

Customers and markets

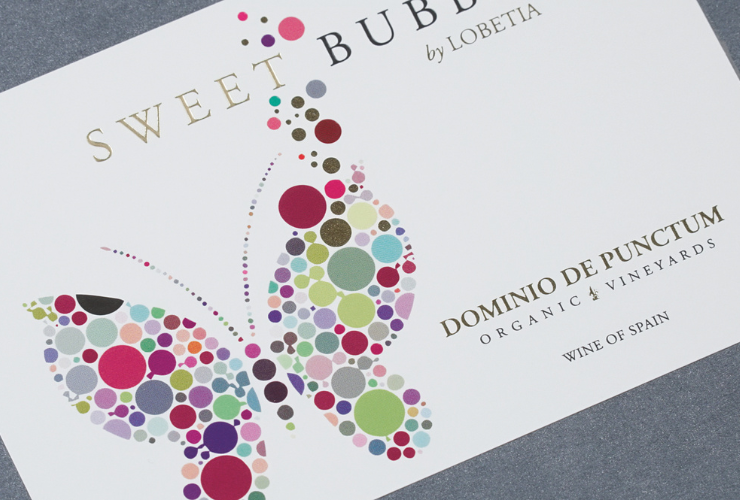

Graficas Tomelloso counts wine cellars and food companies of all sizes among its clients, all of which share the desire to make their products unique, standing out from the competition already on the shelf, where the first interaction between consumer and packaging occurs. To create extraordinary labels, company owners have always invested in research, development, design, and genuinely distinctive technologies.

“In the 1990s, the wine label didn’t have a lot of embellishment, and making a great print was more than enough,” says Patricio Morales, CEO of Graficas Tomelloso.

“In the 1990s, the wine label didn’t have a lot of embellishment, and making a great print was more than enough,” says Patricio Morales, CEO of Graficas Tomelloso.

“Today, on the other hand, clients hire designers and illustrators to dress their bottles, and they involve us to enhance their creativity with stunning special effects, preferably novel ones.”

To exceed its customers’ expectations, the La Mancha based company has added every conceivable form of embellishment to its printing, including unique colours, metallic and holographic foils, spot varnishing, embossed and glitter screen-printed varnishes, embossing effects, micro-perforations and window packaging. With consultative and personalised service, a modern machine fleet, HD flexo technology with digital printing, and numerous finishing options, Graficas Tomelloso effectively handles large quantities and limited runs.

The (repeated) choice of Cartes

What triggered Graficas Tomelloso’s interest in Cartes in 2010 was the need to produce highly complex labels more quickly, profitably, and sustainably, reducing the number of makereadies, manual operations, and waste. Cartes’ ability to integrate screen printing and dozens of other in-line processes, combined with the extreme precision and productivity of the machinery, convinced the Morales brothers it was time to invest in the Italian manufacturer’s technology.

“As well as opening the doors to screen printing, Cartes has radically changed the way we print,” Morales points out. “From the first moment, it seemed a step ahead of the competition regarding construction solutions and quality.”

Cartes GT360 allows Graficas Tomelloso to complete many more jobs per shift, acquire new customers, and produce extremely complex labels in a single pass. To support increasing volumes, in 2013 Graficas Tomelloso purchased a second GT360 with two hot stamping and screen printing units, followed in 2015 by a third, almost twin unit. In 2016 and 2017, the company introduced its fourth and fifth GT360s, while in 2018, it scored the installation of three more lines, all configured with varying numbers of screen printing and foiling units. “Although they are all similar, we have configured each line differently in terms of the number and location of printing units so that each one pander to the specific requirements of our most demanding customers,” Morales explains. “For simpler labels, however, we can use multiple lines in parallel and achieve the same result.”

Having multiple twin Cartes units also facilitates the interchange of operators between departments and the sharing of interfaces and tools to optimise workflow.

Technology pluses that make a difference

In addition to the need to replace outdated machinery, among the reasons why Graficas Tomelloso prefers Cartes’ technology are the many technical advantages, ease of use, and some exclusive features the manufacturer has introduced and fine-tuned over the years. Among all of this, the extraordinary flexibility allows it to integrate downstream of any analogue and digital printing process.

“One of the great pluses of Cartes is its semi-rotary die cutting, which corrects the small defects generated by digital printing presses,” Morales explains. “GT360 has impeccable registration and compensates for the small tolerances that occur in semi-rotary digital presses.”

For about two years now, Graficas Tomelloso has also introduced Cartes Jet D-Screen digital inkjet finishing technology in both multi-pass (on GT360) and single pass (on Gemini platform) versions. Capable of creating thicknesses up to 800 μm, the first can execute high-thickness varnishing and dimensional metallic textures. At the same time, the second allows for quick ennobling of on-demand label orders, without waiting for screen printing plates and frames.

“Jet D-Screen caught our attention because it allows us to achieve thicknesses that are impossible to create with traditional technologies,” Morales points out. “In addition, we can varnish in register even 5-body texts, which are not reproducible in screen printing.”

Graficas Tomelloso looks to a more efficient and sustainable future

Thanks in part to Cartes’ contribution, Graficas Tomelloso has recorded double-digit sales growth in recent years, streamlined production processes, and reduced burdens associated with operator training. By relying on homogeneous finishing lines, the company can effectively distribute large volumes and production peaks, with the security of always having one or more backup machines, even in scheduled maintenance. Graficas Tomelloso has achieved almost total energy self-sufficiency by investing in photovoltaics and energy-efficient machinery. Thanks to Cartes, start-up waste and the relative amount of waste to be disposed of have also drastically reduced.

Fourteen years after the first handshake, the relationship between the Spanish converter’s team and the Italian manufacturer strengthened around values of mutual trust and esteem, and a joint process of research, development and continuous product improvement.

“We cannot imagine our future without Cartes,” Morales concludes. “More than a supplier, it is a strategic ally we rely on for all our needs and new technologies.”

This article is an advertorial; the featured company created the wording and paid for its placement. It has been checked by Whitmar Publications to ensure that it meets our editorial standards.