Portugal-based inkjet digital printing specialist Mtex NS has partnered with Delta Electronics to upgrade its printing machines, with more flexible and scalable technology.

Mtex NS – formed in 2019 by the merger of Mtex and New Solution – offers a range of digital printing technologies targeted at different printing markets, such as fibre and plastic packaging, labels and digital textile printing. Headquartered in Taiwan and founded in 1971, Delta Electronics is a global provider of power and thermal management solutions. The company’s EMEA operations were established in The Netherlands in the mid-1990s.

Mtex NS sought to upgrade its printers by moving away from what is described as a ‘closed and relatively rigid’ legacy control system architecture, in favour of a scalable, more flexible option. Specifically, the new system had to work faster and more precisely and: allow users to select between incremental and absolute encoders; have a reliable STO (safe torque off) function; support EtherCAT connectivity for servo drives and motors; and make it easier for users to programme the machine control system.

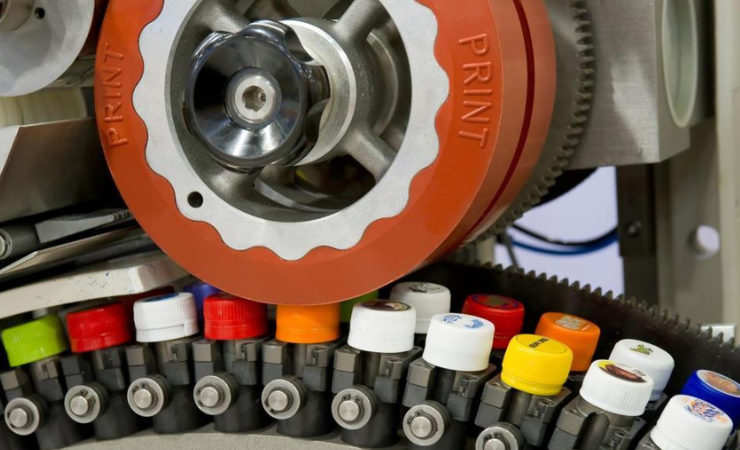

Servo drives from Delta Electronics are central to this upgrade project

The project focused on two pigment printers, Multi 800 and Multi 1300. The first is an entry-level model for creating professional packaging and paper bags, with the second able to be used to apply pigment inks to coated and untreated materials, transfer films and fabric textiles, in addition to card and paper. Both models are equipped with numerous servo drives and motors for precise control. Several Delta components were selected to upgrade the printers. The Mtex NS Multi 800 was fitted with three servo drives of the ASD-B3A-E series and three servo motors of the ECM-B3M series. All the servo devices are connected via EtherCAT to each other and to a MS 300 inverter and an R1-EC gateway. The solution is controlled by an AX308ET motion controller-based on a programmable logic controller (PLC), which communicates via OPC UA with the PC and the UI, which is installed on it. The larger Mtex NS Multi 1300 system was also equipped with similar components, albeit comprising a total of six ASD-B3A-E servo drives, six ECM-B3M servo motors and two MS 300 inverters. As well as ensuring faster and more precise printing processes, EtherCAT connectivity means the printers can be integrated into existing Industry 4.0 environments.

With Delta’s support, Mtex NS has also introduced Codesys automation software to control the ASD-B3A-E, AX-308E, MS300 and R1-EC components. It is programmed through the Delta DIADesigner platform with DIADesigner AX based on Codesys. This programming platform serves as a development environment for PLCs and can be used with axes, drives and slaves from a broad range of manufacturers. Delta organized on-site training for employees to demonstrate how easy it is to use the software, ensuring optimum user acceptance of Codesys. Print jobs are noted as ‘easier to scale’, with Codesys gives employees the opportunity to flexibly programme customer-specific designs alongside standard processes.

Delta has noted that the upgraded digital printers fulfil all the requirements specified by Mtex NS, which has decided to fit a total of 250 Multi 800 and 100 Multi 1300 printers with the new technology. Plans are now being made to upgrade the even larger Multi+ models.

Enric Tamarit, field application manager, Industrial Automation Business Group at Delta EMEA, said, ‘The success of this upgrade project is largely due to the fact that we at Delta have not only supplied the required components but also offered an entire service package, which, in addition to planning and implementation, also included consulting, and a well-designed software training. We have given Mtex NS a complete solution for industrial automation and are looking forward to contributing our expertise to the projects that the business has already planned for the future.’