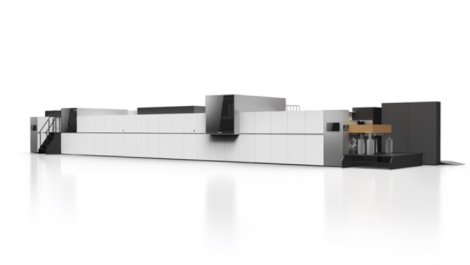

Indiana-based Accu-Label has opted for a second Durst Tau RSCi UV inkjet digital label press, following the success and benefits seen from its first such machine.

Accu-Label installed its first Durst Tau RSCi in 2021. In the aftermath of the investment in this 20in-wide model, it was noted how the company had been able to handle medium- to long-run jobs economically and attain ‘a new standard of quality’. Print speeds are reported as being five times higher than traditional methods and consumable costs have halved. Strategic and commercial gains were made, with the company quickly seeing nearly half of its production being run digitally. Previously, the company, which has been operating digital printing technology for more numerous years, worked on a 25/75% split between digital and flexo.

With one of the company’s key objectives being to see more work transition from flexo to digital, the printer’s production manager DJ Manning said at that time, ‘[The Tau RSCi] has had a bigger impact on our business model than any other investment to date. After only a year, we’re already considering installing a second Tau very soon, to enable us to expand into new market segments.’

Mr Manning noted, ‘With close to 100% capacity on the first unit, it was time to add a second. Capacity and redundancy are such an integral part of our process and we need the quick turn, fast speed and high-quality abilities of the RSCi to open our business to faster turn labels.’

Accu-Label has high expectations with the addition of this second press. Mr Manning said of this next chapter, ‘We are hoping to see our digital transition into more aggressive turn times on labels, giving customers the ability to order as needed rather than keeping large shelf inventories. With having two RSCi’s, we can shorten lead times and ease customer’s supply needs.’