A new generation of inkjet-powered retrofit options promise to bring cutting-edge digital printing to even more of the market, as David Pittman reviews.

Retrofitting digital to legacy print equipment is hardly a new phenomenon but it is an opportunity many are reviewing with renewed vigour.

Mike Barry, key account and OEM manager for digital printing at Domino, examples, ‘The technology transforms existing presses into fully functional hybrid printing machines for a significantly lower cost than a brand-new hybrid printing press. It also allows for additional cost savings from using existing stocks of tools, such as plates and cylinders, and allows converters with space constraints to add new capabilities without expanding their footprint.’

Domino’s new N610i-R digital retrofit module is available in four colours (CMYK) or five colours, including double white (WW+CMYK). The five-colour version allows for printing in high opacity digital white (72%) – often used as a replacement for screen printing – at 50m/min. This retrofit module has been developed for OEMs and converters looking to add digital printing technology into existing flexographic lines for hybrid printing and to help converters to expand the capability of their traditional presses and to give a ‘new lease of life’ to flexo presses that may have been underutilised.

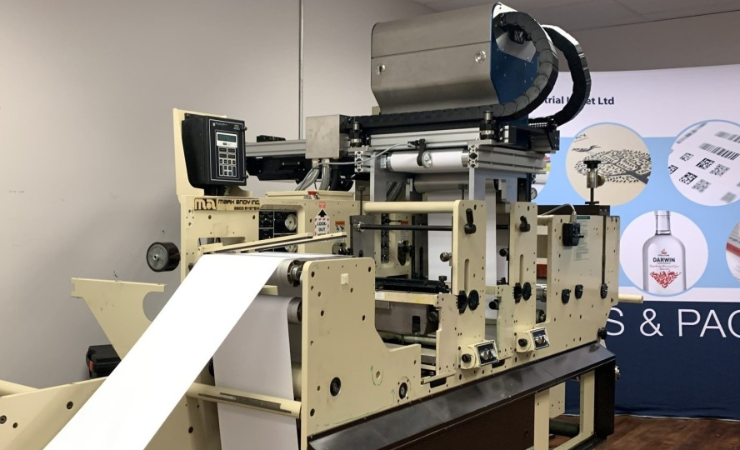

With this in mind and Domino’s existing relationship with Mark Andy to develop hybrid printing systems, it’s perhaps no surprise that DSiQ-R has been added as a retrofit option based on N610i-R, but badged by the flexo press manufacturer as part of its product offering. DSiQ-R is designed to integrate with Mark Andy’s Evolution and Performance Series press platforms to create a hybrid, single-pass production platform.

DSiQ-R is one of a number of retrofittable options that Mark Andy offers, such as its ‘Digital Plus’ series. Digital Plus Variable (DPV), for example, is an inkjet module that adds single-colour variable data capability to new or existing digital/flexo presses or finishing machines, at 600dpi resolution across the web and 300-600dpi in process direction, with speeds up to 150m/min. Digital Plus Screen is then an inline digital print module that integrates single-colour UV inkjet printing into high-output flexographic equipment and negates the need for a rotary screen unit and its associated setup costs. With this unit, tactile effects can be created at up to 73m/min.

Whilst the N610i-R module is a new addition, Domino similarly has an established product portfolio suited to retrofitting and adding digital capability to flexo presses. Xpress Labels has not long since upgraded an MPS flexo press with a Domino K600i inkjet digital printing module, expanding the company’s capability to print variable data. Following this upgrade, the UK printer can print variable data on the face of the labels, the reverse side of labels – specifically on the adhesive side and on the reverse of the backing paper if needed. This has given the company flexibility that, ‘opens new opportunities for personalised and customised labelling solutions for our customers.’

Operating at linear speeds up to 150m/min in dual-bar configuration, Domino K600i’s can print at 600dpi onto a wide range of media substrates. Variable data examples that can be printed using the system include serial, batch, random or pin numbers, as well as alphanumeric characters, linear bar codes, 2D codes or QR codes. Variable images can also be produced. These are applicable for a variety of applications, such as consumer engagement, loyalty and promotional programmes, anti-counterfeiting, food safety, track and trace, brand protection, inventory control, and logistics and reverse logistics.

Another printer successfully deploying inkjet retrofits is First Tape & Label (FT&L) of Texarkana, Arizona. It is using a 3800 Series UV inkjet engine from Colordyne Technologies to produce single-pass inkjet labels for its customers. This is actually FT&L’s second Colordyne system, having acquired a 3600 Series UV – retrofit in 2020. After experiencing faster turnarounds and cost savings through the integration of inkjet technology, FT&L acquired the 3800 Series UV – retrofit in 2021. The latest inkjet engine is mounted on an existing flexo press and it showcases an automatic splice system and job-changing software that allows FT&L to gain efficiency and speed in its daily throughput.

As well as being used to upgrade modern-day servo-driven flexo presses, such systems can also be used to add new capabilities to older mechanical machines, such as Mark Andy’s 2200 and 4150 models. Such machines can also be used us ‘donors’ for digital presses, in so much as that they are used for unwinding, die-cutting and rewinding, with a digital module used to print. This type of configuration has been and continues to be championed by Industrial Inkjet (IIJ), particularly in North America where there is an abundance of legacy flexo equipment available and ready to be converted with inkjet. This allows converters to renew and reuse existing equipment by way of a retrofit, rather than outright buying a new digital press.

Kodak Prosper Plus Imprinting systems can be integrated into a variety of analogue processes, whether flexo, gravure or offset, or even a packaging converting machine. Suitable for corrugated, folding carton, label and flexible packaging applications, these systems are capable of delivering high image quality and high-speed printing, of 600 x 900dpi at up to 600m/min. The systems use Kodak Stream continuous inkjet technology, which delivers ‘precise, round drop placement’.

This, according to Randy Vandagriff, senior vice president, digital print at Kodak, allows packaging printers to implement hybrid printing in a ‘very flexible and cost-effective way’ and allows, ‘high-quality printing on sometimes difficult substrates without compromising the productivity of the entire production line.’

He goes on, ‘Our imprinting systems facilitate the implementation of innovative ideas that change the way packaging impacts consumers.’

Kyocera Nixka Inkjet Systems (KNIS) and Xaar have added further systems into the mix that can be used to upgrade existing hardware and integrate digital into legacy hardware.

Xaar’s Versatex printbar enables label and flexible packaging producers to digitally print ‘the highest opacity whites and colours’ and add a wide range of features to their existing presses. It can handle a wide range of inks and fluids, printing at widths of 410mm and at up to 720dpi with eight grey levels at speeds of up to 75m/min. Textured and high-build print effects, varnishes, foils, and mass personalisation are also available when using this new printbar. From KNIS is Genix 1200, a water-based inkjet print engine that can operate at up to 200m/min. Initially offered as a four-colour inkjet print engine, up to a further three colours can be specified depending on the customer, although Genix 1200 inkjet print engines can be upgraded in the field, as and when there is a need for more colours. Genix 1200 can be integrated into converting lines or retrofitted to existing hardware, ‘giving a second life to the existing and amortised systems, with a state-of-the-art inkjet solution upgrade.’

Modules and printbars dedicated to applying digital embellishments are another option open to converters looking to upgrade their capabilities. Jet-Bar from Omet is a unit for inkjet digital printing of raised varnishes of different thicknesses. This unit can be used in different positions on the company’s KFlex or XFlex X6 flexo presses. Nilpeter’s high-build varnish inkjet unit offers embellishment capabilities suitable for the health, personal care, and wine and spirits segments. Jetting varnish at a resolution of 360dpi at up to 60m/min, the unit is seen as a, ‘unique replacement for traditional high-build and spot varnish.’ The unit can be integrated or retrofitted at any point to a Panorama hybrid press or any other Nilpeter printing press for that matter.

Register here to receive Digital Labels & Packaging