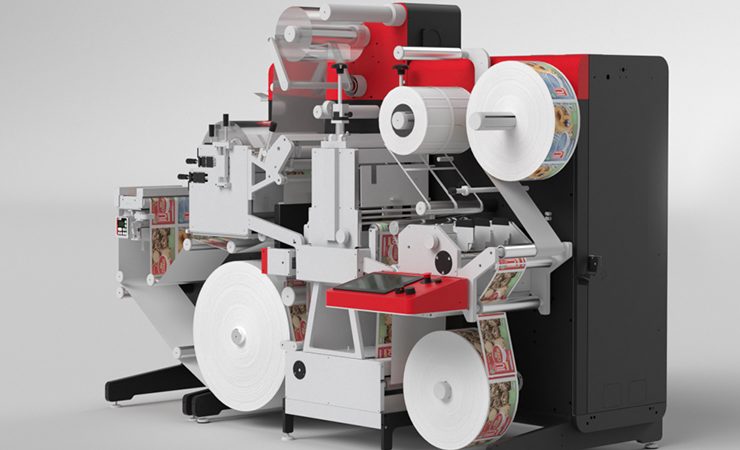

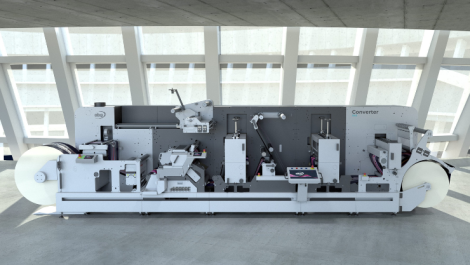

Xeikon has introduced LCU to its portfolio, a new generation of label converting units designed with scalability and flexibility in mind.

Two models are available, with the Xeikon LCU350 a fully loaded machine, with the modular platform affording flexibility and scalability to support business growth. The Xeikon LCU33 is a more basic version, offered as an entry-level choice. All Xeikon LCU models designed to work inline and offline with Xeikon’s Panther inkjet and Cheetah dry toner digital presses.

Specifically developed and designed for converting in high-end label production and manufacturing environments, the Xeikon LCU series has been engineered with a modular and scalable architecture for added flexibility, Cloud connection, and full integration.

For example, the varnishing station comes with an increased width and improved register, and can be upgraded to spot varnishing. Additional flexo stations can be installed, automatic laser die-cutting can be specified, automatic die plate change can be implemented, and hot foil and screen-printing stations can be added to expand the application range. Die-cutting in semi-rotary mode at 80m/min can be increased to a maximum speed of 130m/min in full-rotary mode.

To contribute to the digitalisation of print manufacturing, the Xeikon LCU series has built-in Cloud connectivity for data collection and remote service, and different interfaces can be specified, whether machine-to-machine or man-to-machine. Automation is available for processes, such as optional automatic turret rewind or optional die plate change; and for job information, which allows data transfer to different units

Jeroen Van Bauwel, director product management at Xeikon, said, ‘A key value of our new Xeikon LCU series is in the various different options and levels of investment available to suit the customer’s requirements.

‘As with many of our digital solutions, the Xeikon LCU series is designed to adapt and grow with our customer’s business needs. Through our Xeikon Solution Services (XSS), customised versions and different configurations are possible as the customer’s business grows, depending on the application and volumes required, such as from a basic varnish through to automatic laser die-cutting capability, and wider web versions up to 520mm.’

Mr Van Bauwel concluded, ‘This is an exciting new development for the converting industries. From the converter’s point of view, not only will he now have the latest fully automated and high-quality finishing and embellishing capabilities, but he will also have the flexibility to customise his finishing department and combine a number of different processes to maximise his label applications and extend his label portfolio to grow his business. Xeikon is also addressing customers who are on a smaller budget. The Xeikon LCU33 is an entry-level model designed for smaller business operations. It is an attractive investment, upgradeable and market competitive.

‘With our new LCU series all, processes are now connected in one smooth process from file to finish. With the Cloud connection, the operator can now rely solely on the capabilities of the Xeikon machines. Converters today are constantly searching for new technologies and equipment to enable them to meet the high levels of demand from brand owners for the latest sophisticated and unique embellishments plus high-quality finish to attract consumers. With Xeikon’s new LCU series, they will have all they need to take the next step to full digitalisation in label production and manufacturing.’

Read a technology update on converting equipment in the March 2022 issue of Digital Labels & Packaging; register here to receive the magazine