Spanish converting equipment manufacturer, Enprom Solutions, has secured the first UK order for its eRR40 dual doctoring system, with Leeds-based Olympus Print Group to use the machine as a bi-directional inspection and rewinding system for printed shrink sleeves.

Olympus Print Group specialises in self-adhesive labels, shrink sleeves and large format digital print. From a 55,000sqft site, the company operates across a wide range of market sectors including premium beers, wines and spirits, and household products. In targeting specific markets, the business has invested heavily in its production capabilities over the years, placing an emphasis on futureproofing wherever possible. This has included large-scale investment in digital printing and converting technology, with Domino inkjet engines and A B Graphic (ABG) finishing lines coupled for its customers’ benefit.

Enprom Solutions is jointly acquired by ABG and Kocher+Beck. Its product range includes equipment for shrink sleeve converting, slitting and rewinding, label finishing, coating and lamination, and hybrid converting.

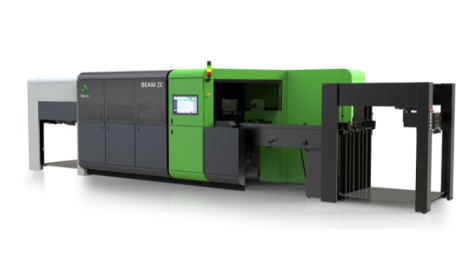

The Enprom eRR40 can be configured in one of two modes: for shrink sleeves, by verifying the correct seaming of the sleeve tube, by means of the balloon validation system with electronic detection; and for the flexible packaging market, by inspecting, checking and doctoring reels up to 400mm web width, allowing for repair printing and slitting defects.

Olympus Print Group will be using its eRR40 as a bi-directional inspection and rewinding system for printed shrink sleeves. In this capacity, the eRR40 consists of a unique, compact and ergonomic unit with integrated unwinder and rewinder, which is designed to unwind and rewind the material and detect defects. The eRR40 can also be complemented with further options.

Adrian Brown, managing director at Olympus Print Group, commented, ‘With a highly specified offline ABG Digicon 3 already playing such a key role in our digital print division, we were expecting the engineering and quality of the eRR40 to be equally impressive; we weren’t disappointed.

‘The compact and ergonomic design of the machine makes this an excellent solution for our business, allowing us to increase productivity without taking up a large footprint.’

ABG sales director Matt Burton said, ‘Olympus recognises that only by investing in new technologies can it continue to meet customers’ ever-changing requirements. As we further expand the ABG range, we are delighted that our long-standing relationship with Olympus continues to grow.’

Olympus Print Group is an active member of the Digital Labels & Packaging Industry Group, which is a collection of leading companies involved in the adoption and increased penetration of digital label and package printing. For more information and to join, email chloe.w@whitmar.co.uk