Midland Regional Printers (MRP) of Nottingham in the UK has installed a Mark Andy Digital Pro as the company works to accelerate its presence within the digital label market.

MRP is already a well-established label printing company with several flexographic printing presses, that continue to operate for volume orders. The additional digital press expands the printer’s options suited to short and medium print runs.

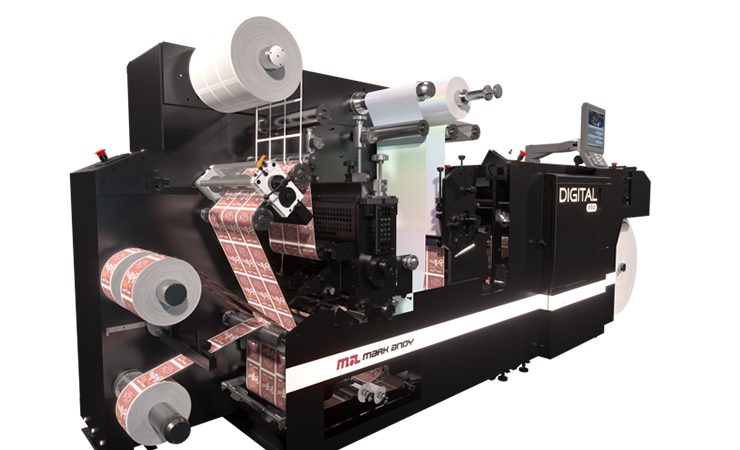

Mark Andy Pro is a toner-based digital press, capable of printing onto all of the existing materials used in MRP’s flexographic department, adding more continuity between the two print processes. The press also runs an opaque white ink to delivers a strong white finish, which MRP identifies as ideal for printing onto clear and metallic substrates.

MRP sales director Catherine Tew said, ‘We’ve been researching new digital label machines for some time now, meeting with all the major machine manufacturers. The quality of the print was critical for us, as we needed to ensure the press we committed to is well suited to the broad range of industries MRP currently supply, from chemicals to high-end cosmetics.

‘We are all very impressed with the quality, performance and technology from the Mark Andy Pro machine and it’s surpassed our expectations.’

Her colleague Matt Seaford commented, ‘The flexo and digital machines go hand in hand. It’s all about producing the best quality labels at the most cost-effective price. This new press benefits our clients with the flexibility to equip their needs, whilst widening our reach to attract new business and to open doors. Brands are already showing a keen interest in this new service and love the reduced lead-times and superb quality.’

Mr Seaford was promoted to the position of sales development director at MRP earlier this year, and at that time said, ‘We are offering more services to more markets and I’m ambitious to grow MRP.’

Following the Mark Andy investment, Mr Seaford noted, ‘With the Mark Andy being an all-in-one print and finishing press, with inline cold foiling, spot UV varnishing, die-cutting and the opaque white, we have an incredibly diverse range of options to accommodate current design trends, whilst offering quick turnaround times.’

In addition, the Mark Andy Digital Pro will contribute to reduced production waste compared to conventional flexographic process, and will bring energy efficiency to MRP as it targets stringent sustainability objectives.