German printer VollherbstDruck has signed on as the first EcoLeaf customer confirmed since Actega Metal Print and AB Graphic entered into a strategic commercial partnership.

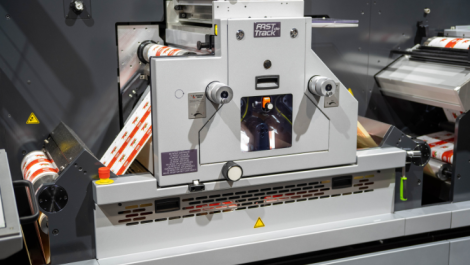

Integrated inline on finishing equipment, analogue or digital printing presses, EcoLeaf combines a printed trigger image and a metallisation unit that applies only the precise and required amount of metal. Overprinting of the silver pigment results in a rainbow of metallic colours, including gold. EcoLeaf was formally known as Landa Metallography and was presented as a technology demonstration at drupa 2016. Designed for a broad variety of markets, EcoLeaf is to be initially targeted at enabling profit-driving metallisation embellishments onto self-adhesive labels. Further packaging applications are under investigation and exploration by Actega Metal Print, a division of Actega, itself a subsidiary of Altana Group. A key component of the EcoLeaf development roadmap is inkjet printing of the trigger image.

Earlier this year, Actega Metal Print and AB Graphic entered into a strategic partnership that sees the UK-based converting specialist handle sales and service of the new EcoLeaf metallisation technology in the EU and the UK.

The introduction of EcoLeaf will enable VollherbstDruck to offer an alternative option to traditional hot foil for a large and growing percentage of its jobs, significantly improving its sustainability credentials. In addition, the new technology will allow VollherbstDruck to customise the metallic colours it can offer, as well as add new applications for its metallised embellishments.

The EcoLeaf option is expected to be installed in September 2020 on VollherbstDruck’s existing AB Graphic Digicon Series 3 converting machine. An ROI of six months has been predicted from the investment, as Matthias Vollherbst, managing director at the printer, explained.

‘EcoLeaf’s sustainability benefits were the primary reason for the order. We had been given a demo of the core technology at drupa 2016, and we immediately saw great potential in this innovation.

‘When Actega acquired Metallography from Landa, we soon started to collaborate and test the technology together. Whereas hot foil has its limitations, EcoLeaf allows us to quickly and flexibly metallise without waiting for foil blocks or embossing tools, and the quality is great. What’s more, the solution is clearly geared to allow large metallised surface areas in the future, which hot foil can’t easily handle, so in time it presents another opportunity for us to expand our range of embellishment options. However, with its immediate benefits, we anticipate increased possibilities for brand owners and swift customer take-up.’

VollherbstDruck specialises in highly refined labels for wines and spirits, currently exports 40% of its products. This sees Vollherbst Etiketten labels serving the French Cognac and South African wine industry, as well as the Swiss confectionery market and others.

Mr Vollherbst continued, ‘Key to our business is providing answers to our customers’ problems. For most, the challenge is in convincing the consumer to take their product from the shelf, and often, to also pay a little more for it. So, our customers’ labels need to work harder than ever. Because of this, EcoLeaf comes at the perfect time. Clients we’ve spoken to are already excited to explore its creative potential and reap the on-shelf benefits.’

Matt Burton, sales director at AB Graphic, said, ‘We’ve known Matthias and his team for many years now. VollherbstDruck is a lighthouse customer for us, representing everything that’s great about our industry and a perfect ambassador for our products. Given EcoLeaf’s unique credentials, we expect this to be the first of many orders to come.’

Jan Franz Allerkamp, managing director at Actega Metal Print, added, ‘We are also thrilled to add VollherbstDruck to our family of customers. It is a very progressive business, and we believe, ideally placed to maximise our technology. We’re excited to see how VollherbstDruck leverages EcoLeaf to push the boundaries of label design.’