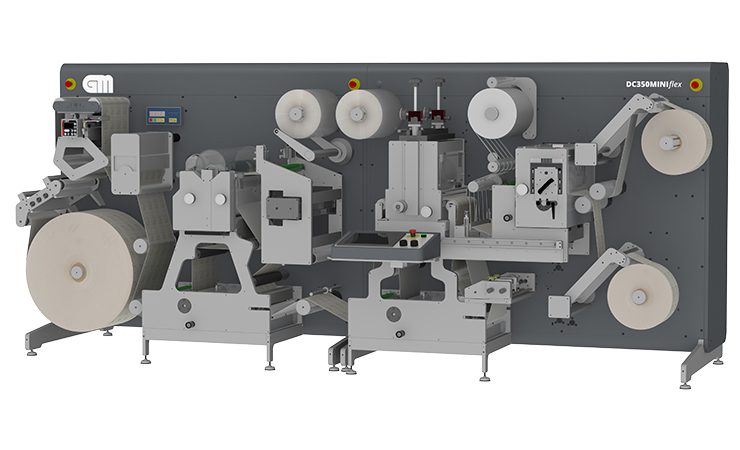

Grafisk Maskinfabrik (GM) has developed a compact integrated converting line for labels, building on its DC350 premium finishing line.

DC350MINIflex has been designed with semi-rotary varnishing, die-cutting, slitting and dual rewind capability as standard, and can be upgraded with value-added options like spot varnish, cold foil, lamination, SmartSlit or SmartCrush slitting, SmartStrip, and more.

The semi-rotary GM SmartFlexo station allows for format free print with only one cliché cylinder, and a registration system for spot varnish and cold foil, while SmartStrip ensures trouble-free operation even while converting delicate substrates and complex label shapes at high speed. The rewinding section can be upgraded with a semi-automatic turret that allows shorter runs to be produced both quickly and more efficiently, according to GM.

The new DC350MINIflex works inline with all major digital presses, and the 350mm web width allows the machine to be combined with digital presses with a larger print width, opening up new possibilities for label converters.

Read more about finishing and embellishment in the March/April issue of Digital Labels & Packaging