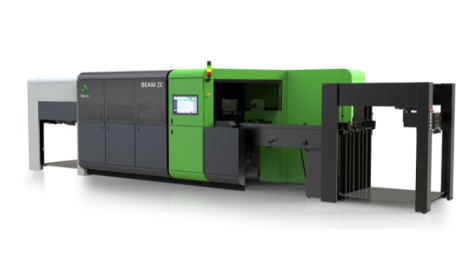

Pennsylvania-based Yerecic Label has invested in its first digital press with inline finishing production line from partners Domino and AB Graphic International. The combined N610i UV inkjet press and Digicon 3 converting unit will give the company the flexibility it was looking for to serve its customers.

‘With Yerecic Label’s focus on lean manufacturing and serving at the ‘Speed of Fresh,’ our digital press cell must meet demanding standards,’ said president Art Yerecic. ‘The Domino digital press and ABG finishing unit allows Yerecic Label to be even more nimble while achieving the consistent high quality our customers expect.’

The company spent over a year researching print quality, conformance to food safety requirements, capabilities and equipment speed from a wide number of manufacturers, before selecting the hybrid machine.

‘Feedback from current users within our TLMI community was a major piece of the equipment research,’ said vice president of production Brian Hurst. ‘The opportunity to visit fellow TLMI converters, see the press and finisher on site and talk with operators was invaluable during our selection process.’

‘We know that the importance of speed, uptime and print quality are key critical to our customers and the success of their business. Domino has ‘engineered out’ operator intervention on the N610i digital UV inkjet label press with automated features of printhead cleaning, stitching and recirculating ink. What that means is that at the end of the day, our customers produce more labels in less time with consistent and repeatable high-quality printing,’ said Bill Myers, marketing manager for Domino Digital Printing North America.

‘We are able to satisfy even the most colour-sensitive customers with the high density dual white ink and six colour expanded gamut (cyan, magenta, yellow, black, orange and violet) that accurately reproduces over 92% of Pantone colours,’ added Mr Hurst. ‘The speed of over 200f feet per minute was just as important in convincing the team that it was time to invest in digital capabilities.’

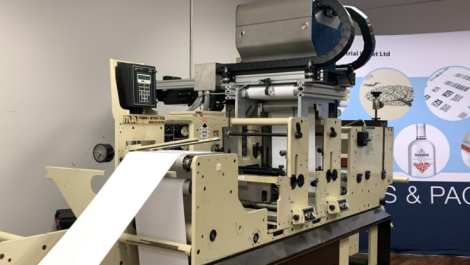

The Digicon 3 includes fleyeVision 100% camera inspection and glueless turret rewinder. ‘When specifying Yerecic Label’s digital solution we realised finishing the product inline was critical to their needs,’ said ABG sales director Tony Bell. ‘Yerecic chose added value for their customers, flexibility and most importantly automation, allowing products to be turned around very quickly, reducing the chance of operator error.’

‘As configured, we’ve already identified over 300 constructions our digital press cell can create in one pass,’ concluded Mr Yerecic. ‘We hope to add to our TLMI Print Awards with our new digital capability. With Yerecic Label’s 50th anniversary coming in 2019, we’re looking forward to continued success with our digital partners, Domino and ABG.’