Whether we talk about CIJ (continuous inkjet) or DOD (drop-on-demand), inkjet technology continues to evolve and find new applications.

The latest digital inkjet systems go well beyond what we normally associate them with by printing colours and coatings on ceramics, glass, and textiles, and jetting functional fluids for 3D printing, printed electronics, and even biomedical and diagnostic applications.

Meanwhile, the modern printing industry faces a multitude of new challenges. Users demand fast printing and quick response times even when the printing tasks change. But also, recent environmental measures within the industry such as the increasing use of water-based inks create challenges calling for innovative and customised technical solutions.

While printhead advancements enabled faster production speeds, ever more powerful DFEs (digital front ends) and software systems driving the mechanical components have had to improve in reciprocity.

Variable data printing (VDP) is a major advantage of digital print. With the increasing demand for personalisation and traceability in packaging and labels the ability to print unique designs, barcodes, and batch numbers in real-time gives brand owners a competitive edge.

In order to maximise its product offering to meet these converting challenges, inkjet press manufacturer Screen, has combined its latest printheads with proprietary workflow management and automation software EQUIOS in its Truepress PAC 830F. The press achieves 1200 x 1200dpi and 75m/min speeds. According to the company, this allows for superior print quality, colour vibrancy, and registration accuracy and ensures that digital printing on plastic packaging can match the speed and consistency of traditional analogue methods, making it a viable alternative for mainstream flexible packaging applications.

Juan Cano, business development director at Screen Europe, said: “With cutting-edge printhead technology and high-speed workflow automation, digital inkjet presses such as the Truepress PAC 830F are now a serious contender in the flexible packaging sector. Converters no longer need to choose between precision and productivity—they can now achieve both while unlocking new creative and business opportunities with digital printing speed, quality, and precision.”

Pump it

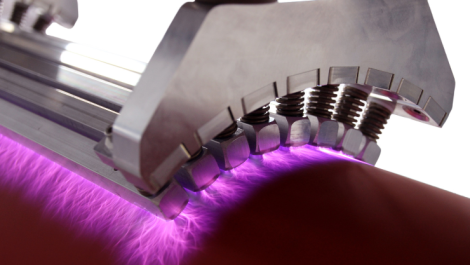

An unsung hero of the inkjet mechanism is the flow pump which helps move the ink around system to exactly where it needs to be.

To fully harness the latest advancements in printhead technology and ink formulations, KNF has introduced a new generation of Smooth Flow Pumps–engineered specifically for high-performance ink delivery systems.

Simon Barwick, managing director at KNF UK, explained: “In today’s inkjet printing landscape, pumps are indispensable. They handle critical functions such as ink supply, recirculation, and degassing. Customers consistently value KNF pumps for their exceptional quality, durability, and customisability, among other key benefits.”

“With smoother ink flow and lower system operating pressure, the load on pumps and other components is significantly reduced–extending their service life.”

Traditional recirculating drop-on-demand (DOD) systems are often complex, relying on a combination of liquid pumps, air compressors, and vacuum pumps. In a typical setup, ink is stored in a bulk tank where a pump agitates the ink to prevent pigment settling. From there, it’s transferred to a secondary reservoir, then to a degassing unit requiring a vacuum pump. The degassed ink flows into a supply header tank, passes through a filter, and is delivered to the printhead in a continuous loop. Unused ink is returned to the system via a return pump, while vacuum pumps maintain the necessary pressure balance to control the ink meniscus within the nozzle plate to ensure optimal printhead performance. Additional purging pumps are used as needed for cleaning and maintenance.

Mr Barwick continues: “KNF’s latest pump technology redefines this process, offering both technical and economic advantages. By reducing the number of components and simplifying the system architecture, KNF enables smaller, more efficient, and cost-effective ink delivery systems that are easier to manufacture, operate, and maintain.

“With smoother ink flow and lower system operating pressure, the load on pumps and other components is significantly reduced—extending their service life. The low-pulsation design ensures quiet, energy efficient, and reliable operation.”

According to the company, another major benefit is the reduction in total ink volume within the system. This not only speeds up purging, cleaning, and priming but also lowers associated costs. In high-speed, multi-pass, or direct-to-shape applications, where the printhead moves rapidly around the object, this compact system design offers a distinct performance edge.

Innovation in action

Dantex Group has opened a new demonstration centre aimed at supporting its digital UV inkjet technology offering. The purpose built facility is designed to provide a controlled, customer-focused environment for evaluating the company’s digital press systems, the PicoJet 1200 DRS and the newly launched PicoColour.

Richard Dimmock, international sales manager- digital, explained the thought process behind the new facility, ‘We wanted to mirror what we had previously at our headquarters in Bradford where we controlled the original demo facility, but now that our digital production has been moved to our Northamptonshire facility, we wanted to have a dedicated area and room for the demonstration facilities that was situated near our local suppliers and the home of inkjet around the Cambridge area. It’s always recommended these machines are placed into controlled environments, so we wanted to replicate what we’re saying to customers when they’re installing our machinery.”

The PicoJet 1200 DRS at its new home in Corby

Dantex was founded in Bradford 1967, which is where the head office still is to this day. From Bradford the company manufactures flexo plate processors, supplies plate material for flexo presses and ink for its digital customers. Dantex Digital was originally established in Kettering, but has since outgrown three former sites, before arriving at this facility in Corby.

Mr Dimmock continued: ‘Customers can bring their own files, they can bring their own material, and we’ll run the press as a full demonstration; whether it’s one day, two days or three days. We bring a lot of international customers here so it’s nice for them to have somewhere that they can call home, somewhere they can set up their laptops and get on with some work while putting the machine through its paces.”

So, what are customers of digital inkjet looking for in today’s market? “Something that they can rely on, to be honest,” said Mr Dimmock. “We have a large client base in the flexo sector, and digital is becoming more and more of a complementary technology to those printers, but it requires a different mindset. Flexo has always been very reliable, it has its challenges, but it’s a technology that customers trust to run and run. They can sleep happy at night with a flexo press. Going digital, yes, it is better for the shorter runs and the more bespoke work, but they want to make sure that an any press investment is running up to 100% of the time, as much as a flexo press can.”

What’s been key to Dantex’s growth in the digital sector? “I think having the ‘Made in Britain’ certification that we have here gives customers some peace of mind that it’s a quality machine, it’s built to be a production machine,” continued Mr Dimmock. “Productivity is also a key factor with our machinery; these days everything is quick turnaround, regardless of the run length, it’s the e-commerce effect. Everyone wants everything the next day, and customers buying labels don’t necessarily care what goes into it – they just want their labels tomorrow. Another trend in the business of label printing is the issue of stock. Printers are now reluctant to have surplus stock for cashflow concerns.”

Dantex Digital is still continuing to grow, with the factory experience a busy June, shipping presses at a rate of one a week. The new demo centre will now help the company accelerate its ability to showcase what its technology can do.

Milestone maker

This year Xaar celebrated 35 years of inkjet innovation.

Founded in 1990, the company’s origins date back even further to work done at Cambridge Consultants, where Xaar co-founders, Steve Temple and David Paton, began exploring droplet ejection for non contact printing.

What began with just four initial patents has evolved into an active portfolio of 150, with more than 2000 inkjet-related patents filed over the 35 years.

John Mills, CEO at Xaar, said: “It was fantastic to bring together our teams from the UK and overseas alongside our guests to celebrate Xaar’s journey.

“From our founding team’s vision 35 years ago to the global business we are today, we’re proud of our printhead technology and innovations which have changed the face of digital printing.

“Be it the step change in reliability with TF Technology or the opening of new applications with Ultra High Viscosity Technology, the passion, creativity and collaboration of our team has driven our inkjet innovation.

“We’re all looking forward to the next 35 years as we continue to innovate and expand into new sectors, supporting new and existing customers to harness the power of inkjet.”

Substrate frontiers

“Digital printhead technology is evolving at an unprecedented pace, opening new opportunities for digital inkjet print. One of the most exciting advancements is the ability to print directly onto flexible plastic films (PET, BOPP, MDO-PE)—a market traditionally dominated by analogue processes,” explained Screen Europe’s Juan Cano.

One of the key challenges in printing on polymeric substrates has been maintaining stable, high-quality results at high speeds using water-based inks that do not slip or slide across smooth plastic substrates at high speeds.

Inkjet printing is also transforming the corrugated and folding carton packaging industries, which traditionally relied on analogue methods like flexography and lithography. These sectors are now embracing digital inkjet solutions to meet the growing demand for short-run, high-quality, and personalised packaging.

“Dynamic manipulation of graphics in real time has led to the adoption of 2.5 Gbit Ethernet connections in systems previously considered low bandwidth”

David Heath, technical sales and marketing manager at Meteor Inkjet, said: “The production of corrugated packaging and folding cartons requires the ability to print vivid, full-colour graphics directly onto substrates. Choosing the right ink type is critical. UV-based inks offer excellent adhesion and durability on non-porous surfaces like coated corrugated board. In contrast, aqueous (AQ) inks, being water based, are more environmentally friendly and suited for porous substrates.”

Meteor Inkjet works with other printer manufacturers who are a good example of an inkjet being used in this way, One such company is Kento Digital Printing, whose Kento Hybrid system combines flexographic and inkjet printing in a single modular line. Flexo units are used for printing solid backgrounds and spot colours, while a single-pass inkjet module handles high-resolution graphics. This hybrid approach effectively reduces digital ink consumption by up to 80% and minimises the need for plates, resulting in a cost-effective solution for mid-sized runs.

Another example is Smartjet, who offer fully digital inkjet printers for overprinting on paper and cardboard. These printers are ideal for small-batch, on-demand customisation, enabling businesses to bring printing in-house and therefore reduce inventory of pre-printed materials. With resolutions up to 1200dpi and speeds of 50m/min, Smartjet’s systems deliver fast, full-colour output without any clichés, plates, or screens.

Mr Heath added: “A key component of these digital systems is the printhead technology. Several printheads are commonly used, such as the Seiko Instruments RC1536, recognised for high-speed, high-volume performance and compatibility with UV-curable inks.”

Processing power

Achieving acceptable print quality requires the machine developer to optimise a complex range of factors. These include RIPing, screening, colour management, ink vibrancy, curing, media control, assembly and mechanical tolerances, ink supply control, and ejection tuning.

“Notwithstanding this complex range of factors, the trend is constantly towards adding data complexity,” said Mr Cano. “This involves more sophisticated rotation and scaling alongside the demand for even higher resolution. Consequently, the data rate between the PC and the printer becomes crucial. Although much of the image data may be static, dynamic manipulation of graphics in real time has led to the adoption of 2.5 Gbit Ethernet connections in systems previously considered low bandwidth. Wide web machines with fully variable printing capability cannot avoid using the more expensive 10Gbit switch gear to receive data from the PC.”