For many converters, investing in fully digital presses represents a substantial financial commitment that may not align with their current operations or business model.

Brand owners are increasingly demanding faster time-to market, frequent design changes, and cost-efficient short runs—requirements that traditional analogue processes struggle to meet economically.

This does not mean however that analogue technology has become obsolete, by any stretch of the imagination, and for many, a hybrid machine can help cater to both worlds and leverage the pros of both technology types. But when installing an entire new hybrid press isn’t quite financially viable, there is another option, retro fitted digital units.

These units integrating seamlessly onto flexo, gravure, and offset presses, as well as converting machines like folder gluers, enabling converters to modernise their operations incrementally whilst preserving their existing infrastructure investments.

PROSPER Plus Systems utilise Kodak Stream Continuous Inkjet Technology, which according to the company enables precise, round drop placement for high-speed operation and excellent ink coverage even on glossy substrates. Operating at speeds up to 600m/min, these systems ensure digital components don’t become production bottlenecks. The base configuration offers 105mm print width, but the system’s scalability allows printheads to be configured up to 12 across, creating customised solutions for corrugated, folding carton, label, and flexible packaging applications.

The performance of PROSPER Plus Systems relies on water based EKTACOLOR Inks, developed and manufactured by Kodak. Beyond CMYK process colours, Kodak offers customised spot colour inks, allowing accurate reproduction of brand colours.

Randy Vandagriff, senior vice president of Digital Print at Kodak, said, “With PROSPER Plus Systems, packaging printers can implement hybrid solutions in a very flexible and cost effective way, allowing high-quality printing on sometimes difficult substrates without compromising the productivity of the entire production line. Our imprinting systems facilitate the implementation of innovative ideas that change the way packaging impacts consumers.”

Adaptability

In an industry where market demands shift rapidly, this adaptability may prove as valuable as the technology itself.

The Domino N610i-R digital retrofit module can be installed on top of existing flexo processes, allowing converters to maximise productivity by utilising full hybrid printing, digital only printing, or flexo only printing – all within the current footprint of their press.

The 600dpi N610i-R digital retrofit module is available with four colours (CMYK) or five colours, including double white (WW+CMYK). The five-colour version allows for printing high opacity digital white (72%) – often used as a replacement for silk-screen printing – at 50m/min. Both colour versions utilise the Domino-manufactured UV92 and UV95 ink set and incorporate Domino’s i-Tech Actiflow, CleanCap, and StitchLink features, reducing manual operator intervention for maintenance and extending printhead life.

Russell Weller, head of digital products, Domino Printing Sciences, said, “The cost of a new hybrid press can be prohibitive for small to medium-sized businesses that cannot afford to discard existing flexo equipment that still has value to their operations. Retrofitting can be a simple, cost-effective solution, delivering full hybrid printing capability for a fraction of the cost of a brand-new hybrid printing press. Converters should look for a supplier offering modules that fit seamlessly above the flexo process with great flexibility of positioning, and the possibility of reconfiguration at a later stage to future-proof the investment.”

Unlock New Value

Retrofitting offers an alternative path to a heavy capital outlay — one that builds on existing investments while adding the flexibility and responsiveness today’s customers demand.

Our Sunday Visitor (OSV), a leading Catholic publisher and envelope supplier based in Huntington, Indiana, USA, needed to meet growing demand for customised envelopes without the expense and waste associated with flexo plates. OSV turned to Colordyne Technologies’ 3800 Series water-based inkjet retrofits.

Before digital integration, OSV managed over 4,500 make-to order runs annually using flexo. That volume risked generating up to 90000lbs (40823kg). of scrap each year. By retrofitting with Colordyne’s inline inkjet engine, scrap has been reduced to virtually zero. This shift has increased capacity by 25 million envelopes annually and eliminated the need to outsource 30 million units that previously had to be purchased from external vendors.

New evolution of Xaar’s Versatex printbar

The impact went beyond waste reduction. By running inline on a W+D 202 RE converting system, OSV could continue producing blank envelopes even when the inkjet heads required maintenance. That operational flexibility meant no downtime and no interruption in delivery, further strengthening customer confidence. After two years of operation, OSV reports virtually no complaints from end users—a testament to the smooth transition from flexo to digital.

With years of experience in producing integrated printing solutions – everything from print engines to production-ready multi-colour print systems – Fujifilm is constantly evaluating its equipment and looking to evolve its product portfolio.

Fujifilm’s range of retrofitting solutions include the SAMBA Mini 4300 imprinting system, the Illumina LED UV curing system and the 42K Printbar system.

The SAMBA Mini 4300 is configurable with one to four individually controlled printbars, providing single-pass printing in monochrome or process colour for a wide variety of production applications, including: coding and marking, mail imprinting, variable data printing, printed electronics, and labels.

The 42K Printbar System is Fujifilm’s newest addition to market for integrated inkjet printing. Launched in June 2021, following the SAMBA 42000 Printbar System, this newer version offers additional features and functionality. The 42K Printbar System, on top of being suitable for direct mail and transactional imprinting, is also expanding into markets that include folding carton, corrugated packaging and other industrial applications. It is suitable as an add-on inkjet printer, or as an imprinting device for hybrid printing.

The system uses 1200 dpi Samba printheads – delivering font sizes as small as 2 point and 1D barcodes as small as 6.7 mils. In a single row configuration, the 42K Printbar offers print speeds up to 300m/min. It is also available in a dual row configuration with print speeds up to 548m/min and can be adapted into any number of different on-site workflow and software architectures.

New directions

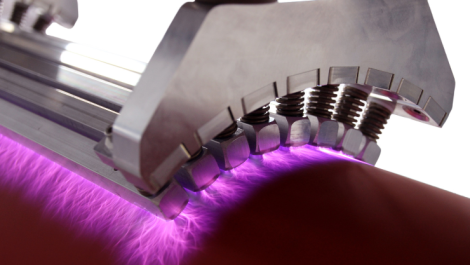

Xaar has launched the latest evolution of Versatex, its high-performance digital inkjet printbar. Designed to expand digital capability across a wide range of analogue print lines and converting machines, the new printbar meets the growing demand for label varnish, foil embellishment and braille.

The new Versatex offers enhanced configurability and easy integration in a compact, low-maintenance design. Now compatible with right-to-left press directions as well as left-to-right, it fits new builds or retrofits without compromising layout or productivity. With many finishing lines running from right-to-left, this new capability makes the Versatex relevant for virtually all installations.

Its on-press interface streamlines job setup and image adjustments, ideal for short runs and variable work. With minimal operator intervention required, Versatex delivers high uptime and consistent output, while its modular, space saving design ensures seamless inline or offline integration into conventional presses and finishing lines.

With sustainability in mind, the Versatex printbar, when compared to screen printing, continues to offer shorter setup times and a higher utilisation rate, resulting in small run jobs being completed faster. In addition, the ability to jet higher volumes and viscosities of fluids – at higher speeds – improves the efficiency of print processes, reducing the need for multiple passes, delivering faster print speeds and cutting energy use and costs.

Alongside the printing of high-opacity whites at 85% in a single pass, the Versatex’s compact, low-maintenance unit features an upgraded Ink Delivery System which increases the high laydown performance by doubling the High Build Print Mode headline speed. For example, jetting 100µm can now be achieved at 50m/min with the new Versatex, compared to 25m/min previously.

Powered by Nitrox printheads, it can jet fluids with viscosities of up to 1000 centipoise at ambient temperature (around 100 cP at jetting temperature). The Versatex’s ability to achieve higher laydown at builds in excess of 200µm delivers exceptional performance for demanding print effects such as varnish and cold foil embellishments, white flood fill, black variable data and digital personalisation.

With Xaar’s High Creativity print mode and High Laydown Technology, customers can achieve laydowns from 15 to 100µm in a single pass – ideal for delivering high-build gloss, spot varnish, and matte textures on premium labels across wine, spirits, cosmetics, and more.

Thanks to the Versatex printbar’s brand new braille mode – with enhanced speed and high laydown capabilities – braille printing is now faster and more precisely defined. This is especially valuable as demand grows in markets like Tom Mooney, Product Manager at Xaar said: “The Versatex printbar delivers exactly what industrial converters and printers need. Whether it is meeting demand for braille and embellishments or driving greater productivity and value in label production – the greater speed, precision and versatility of our new printbar is bringing the many benefits of digital to analogue presses and converting lines.”

Jet technology

JetFx, approaching its 100th installation globally, has built its business around print engines that integrate with existing web finishing presses to create single-pass workflows.

The company offers three systems: SOLO for narrow-web labels, SOLO FlexPack for flexible packaging, and FUSION, a self-contained retrofit module. Each adds capabilities including variable spot varnish, tactile effects, and digital foil to existing press infrastructure.

“We’re giving printers the ability to increase sales and profit margins without the disruption of completely new equipment,” explained Mike Ferrari, marketing director at JetFx.

The latest modules operate at speeds up to 80m/min at 2400dpi resolution, matching performance levels of standalone digital presses. Maintenance is managed through proprietary software handling routine tasks, while the FUSION model incorporates automated printhead servicing to reduce manual intervention.

Labels on Demand, a North American nutraceutical converter, provides validation of the retrofit approach. Their first JetFx SOLO installation added inline digital foil, tactile varnish, and cast-and-cure to an existing GM line.

According to the company, the converter achieved ROI within 10 months through reduced tooling costs, faster turnaround, and premium pricing. Following this success, they added two more SOLO systems and are implementing SOLO FlexPack for flexible packaging. JetFx’s modular architecture allows component upgrades rather than full system replacement. The company estimates total cost of ownership over five years can be 40-60% lower than standalone digital presses, based on utilising existing press assets.

“JetFx is redefining how converters elevate labels and flexible packaging with zero tooling,” says Ferrari. “It’s transformative technology that delivers the lowest cost of ownership.”

For converters with functional press infrastructure, retrofitting offers a lower-risk entry into digital embellishment capabilities.