One of the most valuable assets to a printer is the software which makes the whole production process run smoothly and efficiently. With AI making software smarter and smarter each day, just how sophisticated are the modern workflow systems?

“Let’s cut to the chase: label production isn’t just about the print engine anymore.” Those are the words of Tom Peire, CEO of Four Pees, who believes the true advancements are happening in the backend architecture that links every stage, from order entry to shipping.

“Top-tier label converters now focus on building robust, interconnected systems,” said Mr Peire. “We’re talking about integrating job scheduling, prepress automation, press management, finishing, and quality control; components that were historically isolated. The objective here is clear: slash manual touchpoints, reduce latency, and enable real time status visibility for every stakeholder involved.

“Digital production demands flexibility. One day, you might be pushing out 50,000-unit SKUs for national distribution. The next? Dozens of micro-batches for a targeted online campaign. The challenge is always complexity; variable data, device-to-device colour consistency, last-minute changes. If your workflow isn’t prepared for that, expect bottlenecks.

“That’s where advanced workflow software comes in. Variable data jobs are automatically pre-validated; colour management is embedded, so ICC profiles pass seamlessly from prepress to press. Production monitoring tools deliver real-time dashboards, accessible locally or remotely, so teams can oversee operations from anywhere.”

Feeling the pressure?

“We know packaging businesses are under increasing pressure to deliver more, faster, and with greater precision,” said Craig Tait, chief product officer at ePS.

It’s a pressure all readers of this magazine will understand and appreciate, labels and packaging converters are driven by the market to accelerate productivity, improve agility, and meet sustainability targets, without compromising on control or scalability.

With its latest release, ePS’ Radius ERP now supports both cloud and on-premises deployment, giving converters flexibility in how they adopt and scale technology. Embedded automation, AI-driven intelligence, and open integration capabilities ensure that production workflows are faster, more connected, and more resilient.

Converters can also meet customer and regulatory demands for sustainability through embedded tools powered by ePS’ partnership with CarbonQuota. Users can generate real-time carbon impact estimates at the quoting stage, enabling more informed decisions and helping position converters as leaders in sustainability.

“Carbon has become the universal metric for corporate sustainability,” said Dominic Harris, co-founder at CarbonQuota. “With real-time environmental impact data embedded inside ePS systems, converters can deliver tangible value to their brand clients.”

Closer links to your customers is always useful to enable better communication, as Mr Tait explained, “Radius Hub is a secure, real-time customer self-service portal that extends the ERP directly to a converters’ buyers. Fully integrated and cloud-enabled, Radius Hub provides packaging customers with 24/7 access to their order status, inventory data, shipping documents, and more, transforming customer service from a cost centre into a retention-driving, competitive advantage.”

EPS also offers Paxis, a modern SaaS MIS developed for small to mid sized label converters. Cloud-native and designed for rapid deployment and onboarding, Paxis provides an intuitive user experience and navigation within the system, enabling teams to gain visibility and control over operations without the complexity of legacy systems.

“Paxis holds tremendous promise with its potential capabilities,” said Ryan Casey, CEO of Customizable.com. “Its intuitive design and flexibility are crucial for startups like ours. It’s helping us reduce complexity and streamline operations in ways we never expected.”

From shop-front to front-end

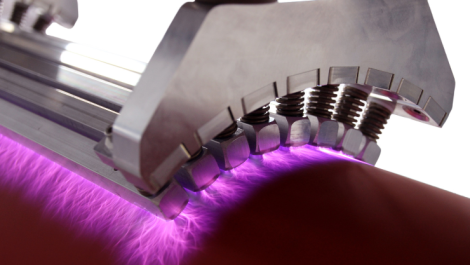

Print software applications work best when it can seamlessly pass production from department to another. It’s this quest for a seamless transition which has driven digital press manufacturer to launch the Sunrise Digital Front End (DFE).

Designed for the Domino N-Series digital label presses, the DFE combines pre-press and production tools into a single workflow. According to the company, Sunrise uses the power of AI and along with the Harlequin RIP to process jobs faster and more accurately.

“Maximising press uptime and productivity is a key priority for converters in today’s competitive marketplace,” says Michael Matthews, product manager – Digital Printing Colour. “Domino is leading the way in using AI and machine learning to create intelligent RIP technology, delivering a highly efficient, scalable front-end solution.”

The latest update to Sunrise combines a set of AI-enabled tools. Modules include Label Studio, which automates repetitive pre-press tasks; variable data processing with inline RIP capabilities; and My Domino Viewer a program which assists monitoring press performance and capturing running data.

“Finding skilled labour can be a challenge for converters, and mistakes can happen,” acknowledges Mr Matthews. “Label Studio enables any operator to automate and speed up pre-press label processing. A real-time preview reflects any adjustments made, maximising press uptime, reducing waste and enabling finetuning before ripping for optimum print results.”

Requests from brands seeking to incorporate variable data, including 2D codes, into their label designs are on the rise, and Sunrise is well positioned to meet this demand.

“Inline RIP of variable data is a game changer for converters,” said Mr Matthews. “Traditionally, jobs containing variable data had to be pre processed while the press sat idle, as RIP speeds were too slow to keep pace with printing speeds. Sunrise breaks down this barrier, processing variable data ‘as-you-print’.”

My Domino Viewer monitors the status of one or multiple Domino presses in real-time, displaying errors, job information, and cost estimates for the current job queue. The data captured can be accessed across a converter’s local network or remotely via a VPN connection. It is also possible to integrate Sunrise with a converter’s MIS and ERP systems.

“Having all this data at your fingertips makes it easy for production managers to identify potential cost savings and process improvements to increase overall equipment efficiency,” explains Matthews. “The tool also allows converters to leverage historical job information for in-depth, retrospective analysis and machine learning.”

“We are dedicated to being a strong partner for converters, listening to understand their business needs, and continually improving our offering to help them meet their objectives,” Russell Weller, head of digital products, Domino, concluded. “We want to empower them to ‘Do more’: enabling them to be more productive and more efficient, produce more labels, and save more costs using Domino digital technology.”

A physical feel in a digital world

Before we even get to the print stage of a job, many brand owners want to see an almost perfect visual representation of what the end result will be. Having a 3D design software can really help speed up the sign off process.

Hybrid Software’s BrandZ business unit has released version 11 of its iC3D software, introducing new features aimed at improving three-dimensional packaging design and artwork automation.

Aimed at packaging designers, brand owners, and prepress professionals, iC3D v11 adds new capabilities that support a broader range of packaging types, including custom stand-up pouches, sachets, and pillow bags.

According to the company, one of the key additions in this release is the Capture 3D Analyzer. This tool evaluates the repeatability of shrink sleeve and metal can production by comparing multiple 3D models and highlighting inconsistencies through a colour-coded heat map. The feature aims to support quality control efforts and aid production decision-making.

“Our goal with iC3D version 11 was to remove friction from the packaging design process,” said Heath Luetkens, sales director of Americas at Hybrid BrandZ. “By combining fast, accurate 3D visualisation with precise layout tools, we’re helping brands eliminate delays and reduce costs.”

When all put together, these tools aim to support a more streamlined and consistent print process. Ultimately a print business can only be as efficient as the systems which run a job from start to finish.