Whether it is folding carton or corrugated board, digital print technology is finding its way into more and more applications along the packaging supply chain.

In a year which sees Labelexpo Europe officially embrace and represent folding carton, it is perhaps an opportune time to evaluate where digital technology sits within the packaging sector, beyond that of flexible packaging.

Although there are many factors which determine whether an application is commercially viable or not, digital print’s reputation for innovation and flexibility is leading some brands over to it.

Michael Strehlow, account manager corrugated EMEA, Domino Printing Sciences, said: “We are witnessing a shift to digital technology for certain corrugated packaging applications, particularly in product categories where numerous products compete for consumer attention. Eye-catching, digitally printed packaging is becoming a key brand differentiator, unlocking the potential to connect with consumers on a deeper level.

“Analogue technology has long been a limiting factor to what converters can offer their brand customers in terms of design variations, with little to no differentiation for converters who want to set themselves apart from the competition. Investing in digital printing technology is a key step for converters seeking to differentiate themselves from the competition.”

One of the key reasons behind this is the rise in popularity for personalised and customised products.

Mr Strehlow continued: “83% of the brands surveyed in NAPCO Research’s Digital Packaging: The Pursuit of Prosperity Report (2024) believe it is important or essential for their printing partner to be able to produce personalised or variable packaging, as they want to deliver a memorable unboxing experience that will enhance consumer engagement.

“Digital technology also gives converters the agility to meet brand demands for faster turnaround. Shorter runs of promotional or seasonal packaging can be produced more efficiently, with less setup waste, while on-demand production virtually eliminates stock waste when packaging designs become obsolete.”

An upset for offset Its not just digital print technology users who are looking into different packaging forms as a way of business diversification, but folding carton producers who are looking to digital to improve their business offering. One such manufacturer is Irvine-based KennedySmith Press which has installed its first digital press in the shape of a Xeikon CX500 to run alongside its B1 litho printing equipment.

Director of KennedySmith, Michiel Molenaar, explained the reasoning behind the installation: “An analysis of our productivity has highlighted the amount of smaller format jobs that we were printing multi-up on our B1 litho presses. They were taking longer to make-ready than to actually print, meaning that they were less profitable than we would like. We decided that this could be the ideal time to take a serious look at digital – the process typically offers virtually zero make-ready, though on a smaller format substrate.

“Having examined a number of possible suppliers, Xeikon seemed to offer us the ideal solution, in terms of substrates available, colour capabilities, performance, and, of course, price.

“We started printing on the Xeikon towards the end of 2023, and the re-training of our litho press operators is still on-going to a degree, but regarding the work produced it has been very successful. The operators are still learning, of course, but if they come across an issue that they have not seen before, there is always somebody on the end of the phone for us to speak to at Xeikon.”

Other benefits of going digital for KennedySmith are that of a streamlined process with no colour corrections. Dealing with companies with footprints spread across the globe, meant that colour corrections could come from as far from Australia, with then more tweaks – sometimes conflicting – from somebody in Canada. With digital files going straight to press, the company can cut out that element of ‘to-ing and fro-ing’.

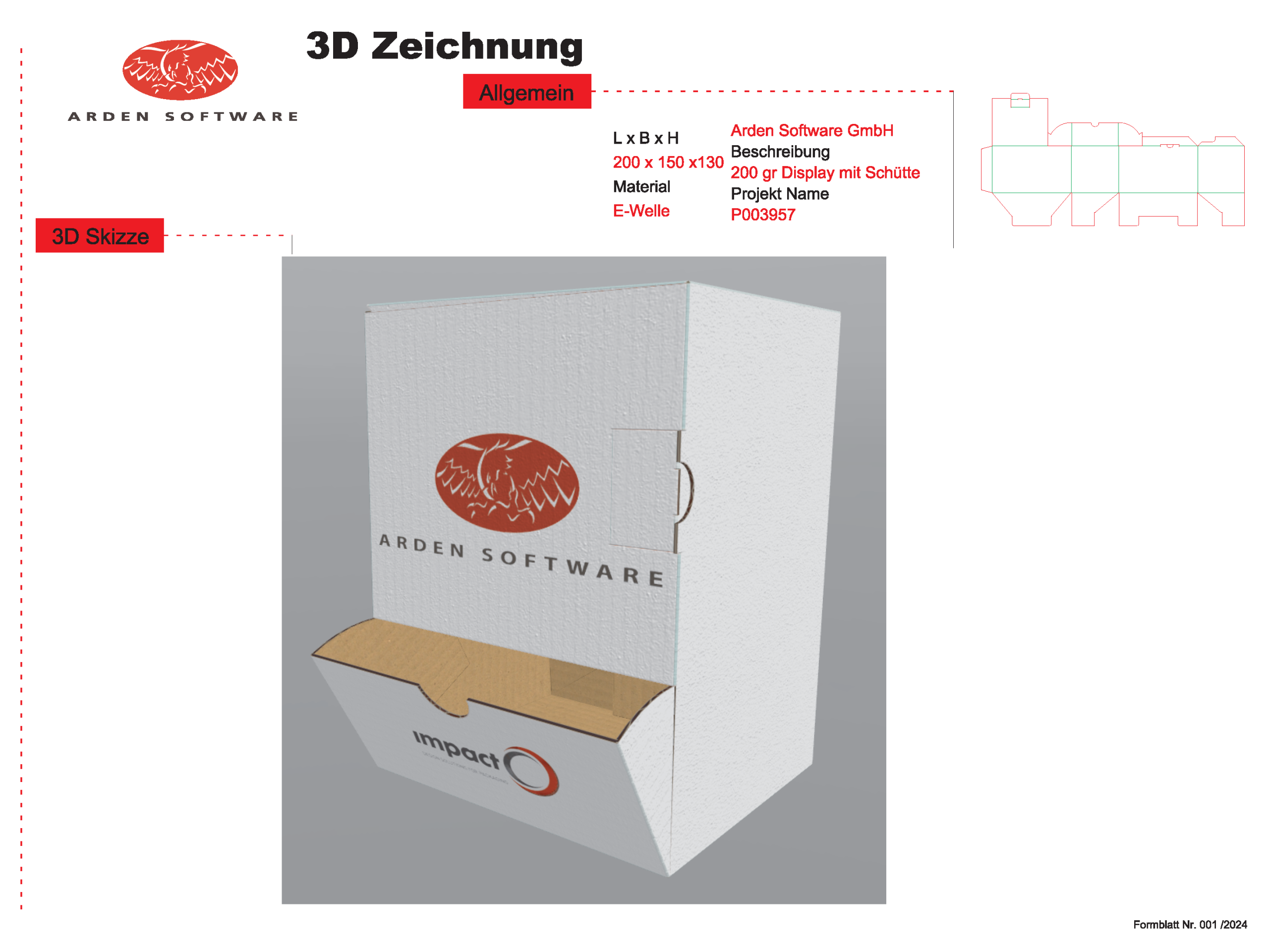

The Arden Impact CAD software performs pre-flight checks, contour recognition, and 3D rendering while determining dimensional parameters and erecting options

Of course, digital print’s arguably greatest attribute, personalisation/ customisation, has given the company the potential of producing security components on pharmaceutical packaging, Mr Molenaar explained: “We are currently talking to one of our customers about adding “best before date” information to their cartons. With others we are looking to produce numbered packs for security, as well as integrating other security features.

“Our shorter runs on the Xeikon are usually about 2500 cut sheets, but we also handle longer runs that equate to 15,000 sheets once we have cut the work from the continuous feed. Both a coating unit and a real sheeter have been added to the Xeikon print engine.”

“We are certainly not disappointed that we have made the move into digital. In most regards it has met our expectations,” added Mr Molenaar. The company is currently running a single day shift on the Xeikon, whereas they would normally be operating a double day shift both on the litho presses and the finishing equipment. “We see ourselves moving forward to the longer working day with the digital press shortly, once we have moved more jobs in that direction.”

Keep it flowing

A German converter’s implementation of integrated workflow systems has demonstrated the potential efficiency gains in quotation and production processes for folding carton applications.

Hans John GmbH Druck & Verpackung, has implemented an integrated system combining theurer.com C3 ERP/MIS software with Arden Impact CAD software through a REST interface. The company was already using C3 as its primary ERP system before adding the CAD integration.

The integrated system operates through a workflow where sales personnel opening a project in C3 automatically transfer customer data, article specifications, material information, and PDF die drawings to Impact. The CAD software then performs pre-flight checks, contour recognition, and 3D rendering while determining dimensional parameters and erecting options. These processed parameters are sent back to C3, enabling quotation generation with 3D previews without requiring CAD department involvement.

Upon order confirmation, Impact stores tooling data while C3 distributes specifications to purchasing, warehousing, and planning departments. This creates what the company describes as a single source of truth, eliminating duplicate data entry across departments.

The system generates step-and-repeat layouts based on C3 specifications, incorporating die-cutting format requirements, gripper margins, waste strips, and bar divisions. Layout data feeds back into the ERP system in real-time, allowing estimators to compare scenarios and assess material requirements, machine times, and contribution margins. Impact simultaneously creates 3D animations stored in project folders, accessible to sales, quality assurance, and customers without additional software requirements.

For production planning, C3 handles scheduling by displaying dependencies between printing, die-cutting, gluing, and finishing processes while highlighting potential bottlenecks.

According to managing director, Thomas John, “The company has observed reduced throughput times, higher quotation acceptance rates, and decreased dimensional error rates since implementing the integrated system. The design department reports increased capacity for new product development due to reduced routine inquiry handling, while sales teams cite improved contract conversion rates through visual quotation capabilities.”

Looking ahead, the company plans to expand C3’s browser based scheduling capabilities with AI functionality for automatic job sequencing based on machine data. Impact is developing features for automatic classification of similar die contours to accelerate variant development and library creation.

This implementation represents one approach to addressing workflow challenges in packaging conversion. The integration demonstrates how ERP and CAD systems can be connected to create continuous information flow across departments, potentially reducing manual data entry and improving process coordination. For converters operating in high-wage markets, such integrated systems may offer a path to maintaining competitiveness while managing cost pressures and increasing product variety. The case suggests that comprehensive system integration may become increasingly important for companies seeking to optimise their digital workflows in folding carton and corrugated product manufacturing.