KNF Neuberger is providing the pumps to help fuel high-performance inkjet systems engineered using Megnajet’s JetSource HFR Core fluid management system.

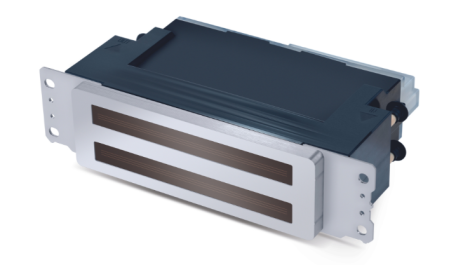

Megnajet is part of Xaar Group and a manufacturer of high-volume inkjet technologies. JetSource HFR Core is a fluid management system designed to meet the challenges of high-volume inkjet printing and additive manufacturing applications. Developed in response to the increasing industry demand for jetting large volumes of fluid, the system recirculates fluid at up to four litres each minute across up to five independent ports for printheads. In addition, the JetSource incorporates a system architecture said to minimise any restrictions and enable peak flow rates to be achieved, ‘thereby maintaining print system productivity.’

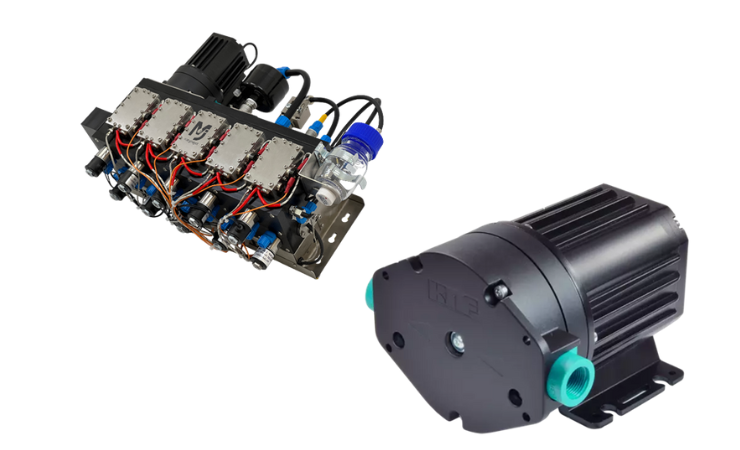

Whilst KNF and Megnajet having been working together for over a decade – KNF and Xaar have been working together even longer – for JetSource HFR Core, FP 400 is being used as a recirculation pump and FP 150 as a feed pump. KNF’s FP pumps utilise diaphragm technology, which allows self-priming and dry-running capability, as well as durability and compatibility with aggressive media. FP pumps also claimed to deliver fluids ‘smoothly, with very little pulsation’.

In the case of FP 400, it affords the ability to recirculate large volumes of heated ink through the system, which is a ‘key enabling technology’ for JetSource HFR Core. By being capable of supplying five printheads with the recirculation necessary for continuous priming and reliability at high temperatures over extended periods of time, it also supports the high laydown capability of the Xaar printheads, which can reach up to 330ml/min each. To accomplish this task, FP 400’s unique custom design features a stiffer and harder FFKM diaphragm, resulting in increased flow. To extend pump life, the eccentric has been reduced to 80% of its original size.

Offering a wide range of flow adjustment and scalability, the KNF pumps’ modular design has allowed Megnajet to select the exact features to meet their specific requirements.

‘Even under the most demanding conditions, KNF pumps have proven their reliability and ensured uninterrupted processes,’ explained Mike Seal, general manager at Megnajet.

‘With their long service life and precise performance, we are proud to have KNF as a partner we can rely on.’