HP has developed a thermal inkjet (TIJ) 108mm bulk printing option, the latest advancement to its TIJ 4.0 printhead technology.

Vice president of speciality printing and technology solutions at HP, Philippe Lesage stated, ’We continue to invest R&D resources in TIJ technology to drive meaningful innovations that enhance productivity, output quality, and unbeatable ease of use.

‘We are excited to offer our customers new ways to navigate an increasingly complex packaging landscape with our growing portfolio of TIJ-enabled solutions.’

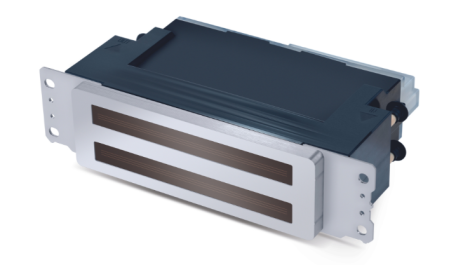

Described as boasting high speed, high resolution, and longer throw distances up to 10mm, the HP 108mm printhead is available to support customers globally with various high-volume printing applications without stitching.

Customers can use HP’s TIJ 108mm solution to print more extensive 1D and 2D barcodes and characters vertically or horizontally at high speed and accuracy. The built-in pressure regulation in the printhead is explained to add flexibility in design with its custom positioning of the ink delivery system.

As clarified by the company, an innovation in its patented micro recirculation technology that reduces pen servicing, means its smart servicing solution can offer clean, crisp prints with fresh ink guaranteed at the nozzle, even when the printhead is left uncapped for 24 to 48 hours.

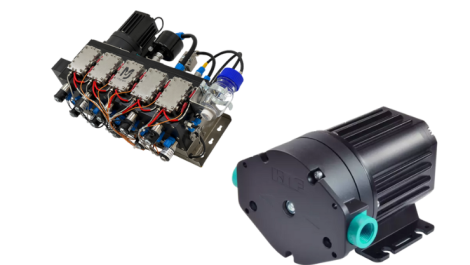

An installation of two bulk supply systems with auto switching, enables supplies to be automatically switched when depleted irradicating a need for a highly trained workforce. Also, low part replacement costs and lower costs per print with bulk cartridges reduce the system’s ‘cost of ownership.’

Pat Harnett director of portfolio, speciality printing and technology solutions at HP stated, ‘The HP 108mm Printhead has been specifically designed to accelerate overall design time and market readiness for OEMs.

‘The printhead and the Ink cartridge can be replaced in minutes without operator training.

‘This allows our customer base to take advantage of continuous printing, reduced downtime, and more seamless production to help offset rising labour and material costs.’