Colour management specialist GMG has released the latest versions of OpenColor – v3.0 – and ColorProof – v5.14 –, both of which have been updated to ‘redefine proofing in the packaging market’.

Both include the new GMG Spectral MX Color Engine, which provides ‘spectacular’ performance gains, such as proof profile calculations up to 15 times faster. Profile quality is also claimed as improved and the profile size is up to 90% smaller. According to GMG, the higher-resolution MXN profiles lead to better colour matching between proof and print, optimising print approvals in the packaging supply chain. ‘In an industry where speed, volume and efficiency are paramount, the advantages are obvious,’ the company stated.

Stefan Zrenner, head of sales d marketing at GMG, reiterated ‘The quality of our proof profiles is crucial for efficient packaging production. The fact that we were able to increase the resolution even further and enhance the precision of these profiles is worth an update in itself. But the performance of the new MX Color Engine, which is up to 15 times faster, is simply sensational. GMG OpenColor and GMG ColorProof are an unbeatable combination.’

A new feature in OpenColor is LAB-to-spectral conversion technology, which allows LAB-based MX4 and ICC characterisation data and profiles to be imported and enables users to switch their entire proof production – including existing, older data – to the more precise spectral calculation model, resulting in a more accurate prediction of overprinting spot and process colours.

Users can also now use the Spot Color CxF export function to exchange spectral reference colour values from GMG OpenColor with other production tools and share them throughout the entire supply chain. In addition, GMG technology partners can access these special ink spectral values via the GMG OpenColor interface.

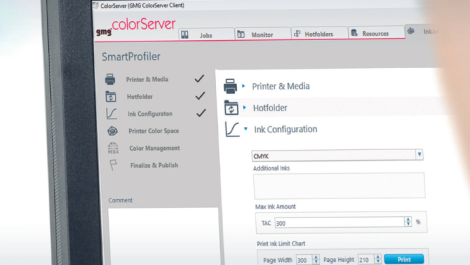

Mr Zrenner continued, ‘With this update, GMG OpenColor users benefit from a central platform where all data and profiles for process characterisation and spot colours are stored. As a result, the same reference data source can be used for both proofing and colour conversions.’