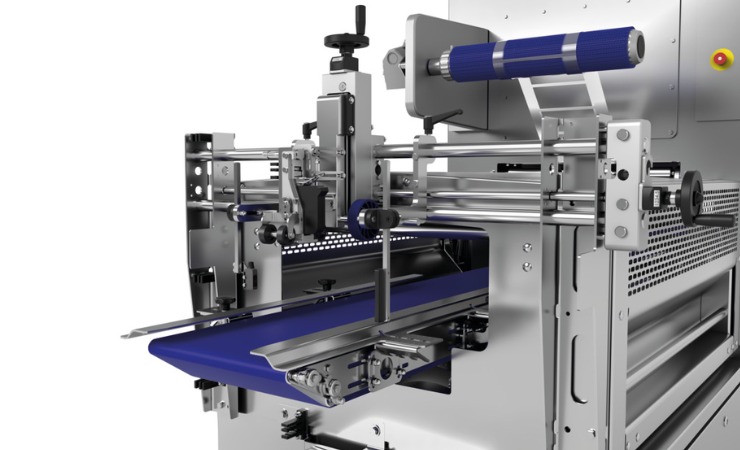

Multivac Marking and Inspection has developed the DP 245, a new direct web printer for the X-line series of traysealers.

Although the model operates at a fixed working height, it automatically adjusts to possible differences in the height of finished packs.

Michael Reffke, product manager for marking technology at Multivac, said, ‘With this new process and IP65 protection, we are taking direct web printing to a new level. Even trays with different product protrusions are marked safely, reliably, and precisely thanks to the new, sophisticated technology. The printing position on the pack can be easily and conveniently adjusted using handwheels, so that batch changes require only minimal downtime.’

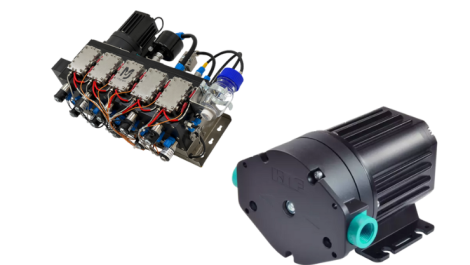

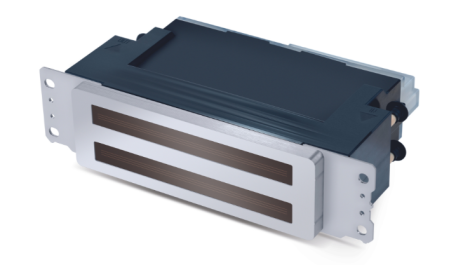

The variable data, such as the best-before date or a batch number, is printed with the Multivac TIJ 10 using the thermal inkjet process. Printing heights of up to 12.7mm can be achieved with one printing head, and even printing heights of up to 25.4mm can be achieved by using a second printing head. As the printer is fully integrated into the operating terminal of the traysealer, Multivac customers benefit from significant advantages in terms of efficient and safe operation. To give just one example, the print layouts are stored in the recipe of the traysealer to ensure that the correct layout is always loaded.

Mr Reffke said, ‘We deliberately opted for the thermal inkjet process in order to offer our customers real added value in the long term. This printing technology involves heating water in the ink. This causes tiny bubbles to form explosively, forcing the ink droplet out of the nozzle. Print resolutions of up to 600 dpi can be achieved, so that even the smallest characters, fonts or codes can be reproduced exactly.’

Unlike continuous inkjet printers, thermal inkjet printers also use print cartridges with integrated printing heads. The new DP 245 is also available in an optional washdown version with IP65 protection, which allows wet cleaning of the traysealer including the direct web printer.