Germany’s Schumacher Packaging Group has reiterated its opinion that ‘digital printing is the technology of the future for packaging’, as it continues to reap the rewards of its installation and commissioning of BHS Corrugated’s RSR system for corrugated sheets and solid boards.

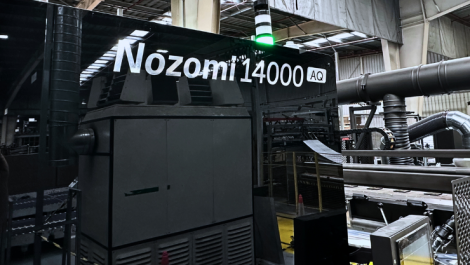

The company is based in Edersdorf, Germany, and is one of the largest family-run manufacturers of packaging options produced using corrugated sheets and solid board. RSR – the acronym for ‘Roll to printed Sheet in Real Time’ – is a new digital-driven system from BHS Corrugated, engineered in partnership with inkjet specialist Screen, and developed in collaboration with Schumacher Packaging.

The fully automated RSR is a water-based system that offers a maximum printing speed of 300m/min. The system has a 2.8m print width, and the printing process comes before converting. As all parts of the system are supplied by BHS, they are aligned to maximise the capabilities of the printing and converting technology, which allows such a high speed to be achieved. The use of water-based consumables, from pre-coating to printing, provides environmental benefits. The inks used comply with the Swiss Consumer Goods Ordinance and the Nestlé Guidance Note on Packaging Inks. Defect detection across the line ensures that only defect-free corrugated cardboard packaging reaches subsequent production stages. Further, RSR integrates with MIS software and other workflow tools to further help optimise production.

Björn Schumacher, managing director at Schumacher Packaging Group, previously went on record to state, ‘We are convinced that digital printing is the technology of the future for packaging made from corrugated and solid cardboard. On the one hand, this is the only way to meet the ever-increasing demands of customers and consumers for high-quality packaging. On the other hand, it can also be used to economically implement small print runs.’

With the system now up and running at the Schumacher Packaging site in Greven, Germany, the company’s digital print manager, Johannes Pieger, has confirmed, ‘The possibility of printing e-commerce packaging individually with variable data and a speed of up to 300m/min has not only been convincing since its commissioning, it helps us to meet the currently scarce production capacities on the market and at the same time increases the flexibility and speed of our customers.’

Read more about the potential for and reality of digital corrugated printing in the July/August 2021 issue of Digital Labels & Packaging; register here to receive the magazine, for free