V-Shapes has launched VS dflex, a nearline reel-to-reel machine for printing the top layer of its unique single-dose sachets.

V-Shapes is a supplier of vertically integrated products and services for convenient, hygienic and sustainable single-dose packaging, which can be opened with a single gesture using one hand.

VS dflex has been engineered as a compact, professional-grade printing system. Powered by Memjet DuraFlex inkjet digital printing technology, the system is claimed to ‘make it easy to print flexible packaging on site’, thereby eliminating the need to outsource printing or to tie up other printing equipment in the plant, especially for shorter runs of customised sachets.

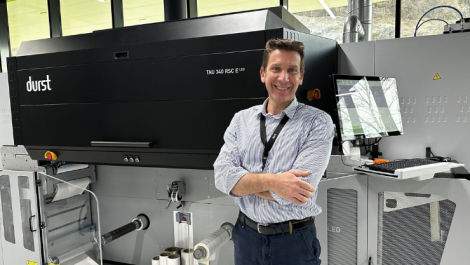

The V-Shapes VS dflex nearline printer powered by Memjet and ColorGate, ready for use with the V-Shapes Alpha fill and seal packaging/converting machine

The VS dflex reel-to-reel nearline printer takes advantage of the speed and image quality of Memjet’s DuraFlex multicolour A3+ printhead and water-based pigment inks, along with the advanced features and colour management capabilities of the ColorGATE Packaging Productionserver, a RIP and colour management option for industrial packaging printing to deliver high quality, colour-accurate printing at 1600dpi at a speed of up to 24.7m/min (90ft/min). It uses certified recyclable substrates, either sourced from Sihl or with V-Shapes proprietary materials.

VS dflex inks were designed for food packaging and specially formulated for quick drying after printing, allowing the substrate to be ready for use with the V-Shapes Alpha fill and seal packaging/converting machine. A touchscreen interface allows operators to efficiently manage the printing process with minimal training required.

ColorGATE has also developed a bespoke Output Management Set specifically for this printing system that takes into account the Memjet DuraFlex architecture and brings all of the appropriate ColorGATE capabilities to the system for the ‘utmost in printing productivity and quality’. In addition, its Rest API interface opens up for V-Shapes future opportunities for more workflow integration as its products and technologies continue to evolve.

VS dflex follows on from the introduction earlier this year of a system developed in partnership with TrojanLabel that seen its T2 high-volume digital inkjet press integrated inline with the V-Shapes Prime packaging machine.

V-Shapes CEO Christian Burattini said, ‘We have always had an objective of making high-quality printing available for our packaging/converting machines, to meet customer demand for faster time to market, personalisation and more. We accomplished that earlier this year with the integration of the TrojanLabel T2 high volume digital label press into our V-Shapes Prime single-lane packaging machine, and we have plans to integrate inline printing into our six-lane Alpha machine as well. But for those Alpha machines already in the field or that will be acquired prior to availability of inline printing, we have developed VS dflex, a more productive reel-to-reel printing solution that makes it easier for packaging converters/fillers to accomplish the complete manufacturing process for our unique single-dose sachets under one roof with a compact footprint. In this configuration, the bottom layer of substrate is printed inline in black only.’

He continued, ‘Our strategic partnership with Sihl is particularly valuable thanks to the ability to print very high quality with aqueous ink and no pre-treatment on Sihl Artysio laminates. It also has our specific materials stocked in Germany and the US to ensure fast and timely delivery.’

Russell Boa, senior vice president, sales, North America and EMEA at Memjet, added, ‘We are excited by the addition of VS dflex, the latest nearline printer from V-Shapes for its inline print, form, fill and seal packaging system. VS dflex enables professional printing with vivid colours, beautiful precision, simply and cost effectively at high production speeds. The combination of V-Shapes leadership in packaging innovation and technology integration makes them a first-class partner to work with.’

On ColorGATE’s participation in the development of VS dflex, Oliver Luedtke, the software company’s chief marketing officer, stated, ‘ColorGATE, unlike many other RIPs and colour management vendors, has focused on industrial markets for the past decade, making this collaboration with V-Shapes and Memjet perfectly in line with our strategies and capabilities.

‘We have had a very productive relationship with the creative and innovative team at V-Shapes. We are absolutely aligned with them in the desire to bring top-notch colour quality, digitisation and Industry 4.0 compliance to the package printing process.’