Digital printing expert HP Indigo and substrate specialist Sappi have joined forces to advance the use of paper in flexible packaging applications.

The companies noted that demand for recyclable, paper-based packaging as a substitute for less sustainable materials is increasing. As such they were keen to combine their respective knowhows to provide the packaging industry with a more sustainable option to suit current and future demands. The new challenges manufacturers will face are cited as smaller product quantities, as produced by flourishing small businesses and start-ups; increasing demand for faster production and delivery; an ever-increasing variety of products; and a trend towards more personalised campaigns. The need for faster, customisable and reliable production procedures is also becoming ‘crystal clear’. This reflects recent findings presented by industry association Finat.

To present their offer to suit such demands and trends, Sappi’s Guard Gloss 4-OHG has been used to create demanding and challenging, digitally printed three-side-seal soup pouches. This project created a paper-based option that renders additional special coatings or laminations ‘superfluous’, and which is verified for the HP Indigo liquid electrophotographic (LEP) digital printing process. Sappi Guard Gloss 4-OHG in a grammage of 91g/sqm was used for these pouches.

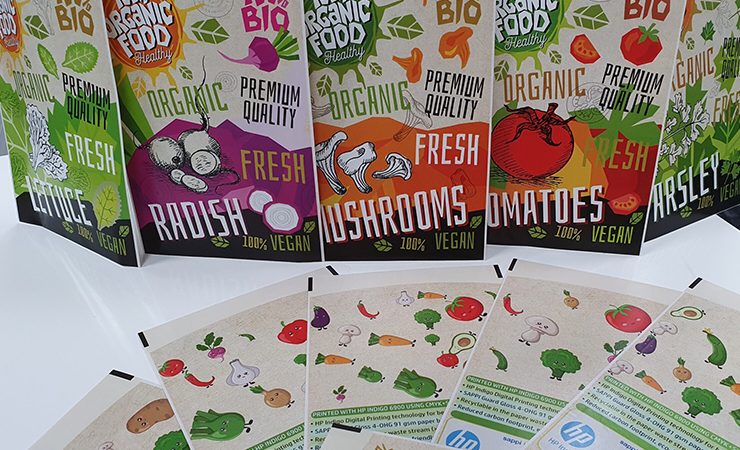

At the HP Indigo Graphic Experience Center in Barcelona, the three-side-seal soup pouches, measuring 130 x 86mm, were given individual designs. Six different and unique designs were used to illustrate various vegetable soup flavours. For printing, a narrow web HP Indigo 6K digital press was used, running the press’ full colour range, in addition to silver and special invisible yellow inks for brand protection purposes. A water-based gloss coating with high heat- and scratch-resistance, ACTDigi Protective Coating AQ440125 from Actega, was applied to remove the need for additional lamination, and to protect the print through processing, filling and transport. The pouches were then finished by Bossar Packaging using its horizontal form-fill-seal equipment for manufacturing flexible packaging.

This all required a material that could endure the different steps from printing to further processing, and which also had strong sustainability credentials. Guard Gloss 4-OHG is a glossy paper that features a functional high barrier against oxygen, water vapour, grease, mineral oil and aroma, and is coated on one side (reverse side). The heat-sealable material is recyclable and based on more than 80% renewable sources. It is suitable for direct contact with food, so can be used for several applications, from noodles, rice, confectionary, powdered products, cereals, crisps and other dry foods, to fatty foods and ingredients. The material can also be used for non-food products, such as dishwasher tabs and seeds.

Kathrin Böhmüller, sales support manager, consumer goods and self-adhesives at Sappi, highlighted, ‘Over 80% of the high-barrier paper’s materials originate from renewable sources. The paper-based packaging solution makes additional special coatings or laminations redundant and the materials can be recycled in the paper stream.’

René Köhler, head of new business development, packaging solutions, with Sappi Europe’s Innovation & Sustainability division, reiterated, ‘With our innovative functional paper packaging solutions we are offering a sustainable material based on renewable sources that can be recycled in the paper stream.’

Eli Mahal, head of labels and packaging product marketing and management at HP Indigo, said, ‘HP Indigo is collaborating with Sappi to validate high-grade substrates that can meet our customers’ requirement to reduce the impact of packaging on the environment, while leveraging HP Indigo’s ability to deliver on-demand, high-quality packaging with minimal waste.’

Read more about sustainable packaging developments in the March/April issue of Digital Labels & Packaging; register here to receive the magazine, for free