Screen and CGS Oris have developed a technology that predicts halftones from limited colorimetric data by using a proprietary algorithm, and automatically generates complete CxF data.

In labels and packaging, spot colours are often used to accurately reproduce brand colours. Especially in spot colour printing, the colour exchange format CxF is regarded as one of the best methods to capture and to transmit all details of a colour. Unlike conventional ICC profiles, CxF data includes the spectral information of the spot colour, including halftones and transmittance, therefore allowing accurate colour calculations and an optimal basis for a precise colour reproduction at any time.

However, as the two companies note, the generation of CxF data takes enormous amount of time as it requires printing charts, measuring colours for each printing conditions and target values. Conversely, the number of digital presses has increased, printing methods have diversified, and there is a growing need for skill-less independent colour management that reliably ensures the reproduction of consistent colours across a press fleet.

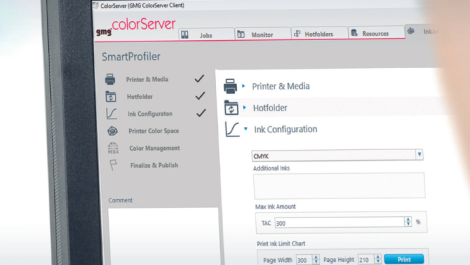

Now though, the technology is available for the CGS Oris CxF Toolbox, a system which stores, edits and communicates brand colours rapidly, reliable and securely. A user just needs to output colour charts under certain printing conditions and put the colour measurement data into the CxF Toolbox. Once the setup is ready, the system can automatically generate CxF data of the particular spot colours or entire libraries without requiring any colour expertise. The generated CxF data can be easily embedded in PDF files to be used for a pre-press process.

CGS Oris stated, ‘As a result, the entrance in working with CxF data was enormously facilitated and the efficiency for users who already work with CxF data has greatly been improved, because both save huge amounts of time in generating CxF data. Therefore, more companies can benefit of the advantages of CxF as it ensures a holistic communication of a colour and provides the best fundament for reproducing (brand) colours on different printing presses, and a flexible and independent colour management regardless of the skills of the operator.’

The CxF Toolbox is seamlessly connected to the CGS Oris Color Cloud, which is a Cloud-based option provided by CGS Oris to communicate all stored CxF data with the entire supply chain. It guarantees access to complete colour data that is always up-to-date, and the availability for each authorised user at any point in time and any place in the world. Even large amounts of CxF data of brands can be organised and communicated with the CxF Toolbox and the Color Cloud.

Screen’s new Truepress Jet L350UV SAI processes PDFs with embedded CxF data and is able to separate them into up to six colours of CMYK+OB. In combination with CGS Oris’ multi-colour separation technology, X Gamut, this allows Screen’s inkjet technology to reproduce spot colours even with an expanded fixed ink set in a high printing quality.