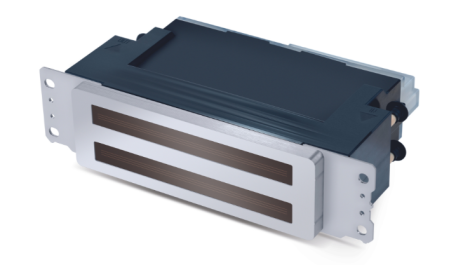

DTM Print has introduced the LF140e digital finisher, completing its production chain for on-demand production of small and medium label runs.

DTM describes the LF140e as ‘a compact system for simple, fast and cost-efficient label processing on-site.’ It can be used to handle all the operations involved unwinding pre-printed rolls, laminating and digital contour cutting, waste matrix removing, slitting and rewinding the finished rolls.

It can process pre-printed rolls with a media width between 100 and 140mm and a maximum roll diameter of 200 mm.

Other notable features include the finisher’s optical black mark registration, an integrated touch screen where all functions and processes can be controlled, and numerous connections such as USB, Ethernet and WLAN connectivity for accessing external cutting jobs.

‘We are excited to offer our customers the DTM LF140e with immediate effect,’ said Andreas Hoffmann, managing director of DTM Print. ‘It offers the user full flexibility, unlimited variations in label design and a smooth workflow. We believe it will be of interest to a wide range of companies, especially those who want to have full control over their entire label production, with coordinated equipment from a reliable source.’

DTM says the system, which retails for €9,995 and arrives fully assembled, offers borderless output, time and cost systems and resistance of the labels. The company is also offering its customers the finisher alongside the OKI Pro1050 at a price of €23,495.