UK-based independent craft brewer BrewBoard is using direct-to-can digital printing to expand its range of exclusive and original craft beer can designs.

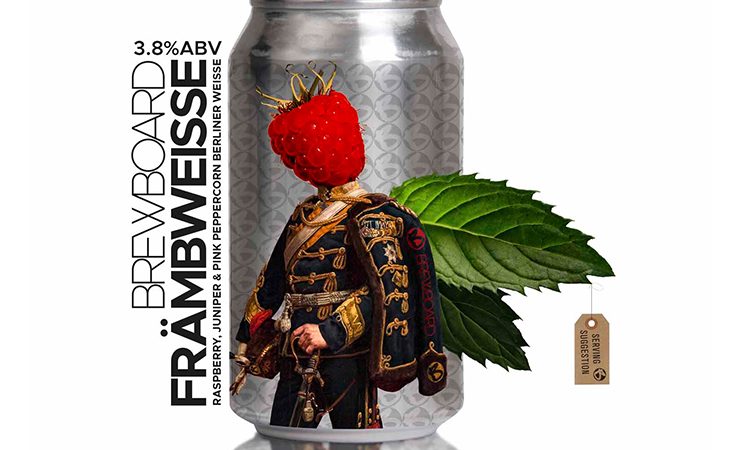

BrewBoard is located in Cambridge and offers a number of core and special craft beers, such as Cardinaldred, Ripchord, Bambino and Rex, and Gonzo, Sacristan, Silkie and Frambweisse. The brewer prides itself on producing craft beers with distinctive and characterful branding. Each brew is distinguishable by its packaging, with unique off-the-wall designs representing the various brews. This is said to be a ‘perfect fit’ for Tonejet, with a minimum quantity as low as one, and giving BrewBoard an edge in the highly competitive world of craft beer.

Tonejet CEO Rob Day said, ‘BrewBoard gives us the perfect opportunity to collaborate with a local partner to expose the full potential of the Cyclone end-to-end model. This is the first of many projects, craft beer is a huge potential market for digital beverage can production.’

BrewBoard co-founder Oliver Pugh said, ‘Having the flexibility to do small runs will enable us to win business that we might otherwise have not been able to cater for. It reduces lead times making us more competitive. We’re very lucky to be located so close to Tonejet; it was a no-brainer to collaborate with them and we are only at the beginning of our digital journey.’

Tonejet’s Cyclone direct-to-can digital printing technology uses electrostatic drop-on-demand printing technology, achieving a 600dpi greyscale CMYK resolution at a speed of 60 cans a minute. SoluCan in Canada has installed the world’s first Cyclone system and has detailed its early success with the technology, with plans to expand its geographical footprint as a result of the investment.

BrewBoard is utilising a Cyclone system installed by Tonejet at its facility in Melbourn, Hertfordshire, where the systems are built and a line is maintained for demonstration production runs. BrewBoard will use this capacity to implement highly customised campaigns across Cambridge and East Anglia. The company has already manufactured thousands of cans with Tonejet and plans to produce many more, as part of custom, short-term marketing campaigns.

It will also allow the company to offer a more sustainable, environmentally-friendly packaging decoration option as the Cyclone system does not use plastic shrink sleeves, meaning the only materials used are 100% recyclable. This gives the process a claimed low carbon footprint, which is compounded further by the process using 90% less ink than conventional inkjet systems.

For BrewBoard, this was one of the main draws for using the Tonejet system, with Pugh affirming, ‘We are always looking for ways to make our packaging more sustainable, recyclable and environmentally friendly and digitally printed cans fit in with that philosophy.’