Graphtec GB has unveiled a larger version of its F-Mark automatic digital die-cutting machine.

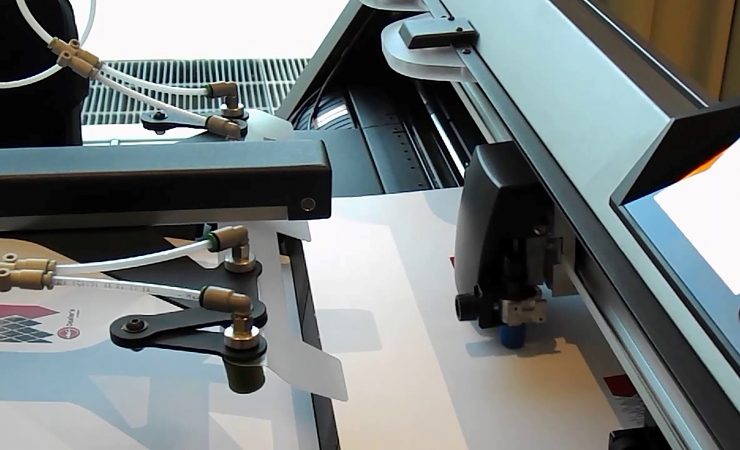

The new cutter comes with a dedicated creasing tool and will die- or kiss-cut sheets of printed material up to 700 x 500mm, including thicker and heaver materials up to 400gsm, via an increased 450g cutting force.

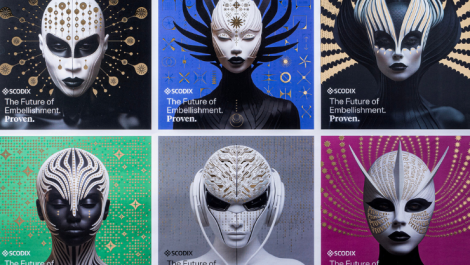

It can cut from the reverse of the sheet to ensure that the printed surface remains unaffected by the score/fold lines of the cutting process and because this process is carried out automatically, there is no requirement for cutting dies.

Up to 200 sheets of pre-printed material can be loaded into the integrated cutting head simultaneously, with the ability to add further sheets as required without interrupting the cutting cycle.

A built-in CCD camera equipped with F-Mark technology detects the two-point registration marks for precise alignment of the contour and the printed image, in addition to compensating for any distortion of the material during the printing process.

The cutting parameters set by the dedicated software allow for the use of crop marks as small as 4mm and the cutting speed for each printed sheet is on average 30-40 seconds. The machine is equipped with an internal vacuum compressor, removing the need for an external air supply connection.