As an event intended to drive innovation and business in primary and secondary packaging, Packaging Innovations connects brands across the FMCG world with hundreds of suppliers, creating a sourcing platform and delivering networking and learning opportunities for the whole community.

This includes companies from up and down the digital package printing supply chain, from hardware and material suppliers to the printers and converters themselves looking to engage with brands and retailers in attendance.

Suppliers

Visitors to the AM Labels (K02) stand can see a preview of the Afinia x350 digital roll-to-roll press, a high-volume label and flexible packaging press for use in various industries including food, beverage and chemical. AM Labels also showcases a brand-new range of label applicators from LabelPack. This includes the entry-level X-Sticker, a wipe-on applicator for label widths of up to 140mm and Label X JR, a fully automatic wipe-on applicator designed for medium- to high-speed applications. There are also working demonstrations of the Epson Scara T6 robot, presentations of colour label printers from Afinia, Epson and OKI, and labelling materials and linerless label printers as environmentally friendly alternatives to traditional materials and methods.

KTEC Group (A16) will have a variety of technologies on show, from desktop printers to software and applicators, as well as presenting A1 Labels to attendees, a recent addition to the group that manufactures blank labels and slit rolls ready-to-use in digital label print and finishing systems.

With the environment in mind, Kurz (M38) introduces a new 10 micron transfer carrier used in the production of its foils. Within this business year, the company is to move all 12 micron products to a 10 micron carrier. This 16.6% reduction in material and carbon footprint will deliver longer rolls, better coverage and less waste. For cold transfer in sheet-fed and narrow web applications, an option to reduce the carrier by 50% is to be offered, resulting in an extremely thin six micron film. Also presented is the company’s take on current trends and packaging design, ‘boxes’, and the return of ‘Make a Mark’. This latter project is a global collaboration with Avery Denison and Estal, inviting 18 design agencies from around the world to come together to create an inspiration platform for the wine, spirits and beauty sectors.

Hybrid Software (C72) brings the latest versions of its Packz PDF editor and Stepz VDP tool to the show, alongside systems and tools from recent additions to its portfolio, such as iC3D’s 3D visualisation software and the 3D scanning and image processing technology of Quadraxis.

Vivid (D66) demonstrates its Zip Core packaging software, a CAD/CAM suite created to optimise every aspect of packaging design from start to finish. This provides tools that speed up and automate everyday jobs of packaging designers, graphic designers and salespeople involved in the creation and production of packaging. Also on show is the award[1]winning VeloTaper fully automated flatbed taping system. This applies double-sided tape accurately onto a variety of media and or substrates automatically in the designated spots. It is capable of automatically placing and cutting a range of double-sided tapes up to 22mm in width precisely along the X and Y axis.

Over at TTR Euroworks (E60), thermal transfer printers, printheads and ribbons are shown. Thermal transfer ribbons are from the company’s own 4U brand, from low-cost wax to high-end resin options, whilst as a partner to multiple hardware suppliers, printers from the likes of Zebra, Sato, Argox, Honeywell and TSC Printronix are on show. Sister company PIY Ribbons shows a printing system that allows text, patterns, emojis or logos to be added to personalised satin ribbons.

Humidity Solutions (P60) brings its experience in specialist humidity control and related products to the show. This is noted as important as print and packaging companies invest large sums in printing and packaging equipment, as well as paper stocks, but without proper humidity control machines and paper stock are exposed to uncontrolled environments where climatic conditions may change hourly, causing issues in production and ultimately impacting the bottom line. Humidity Solutions works on a case-by-case basis, with each option tailored to the particular condition of the building and the types of machinery being used.

Printers

For printers exhibiting, the event presents an opportunity to showcase investments in technology and how it has tangibly benefitted their capabilities.

For example, Olympus Print Group (C76), part of the All4labels family, showcases its expertise in self-adhesive labels and shrink sleeves, produced using Domino inkjet digital printing technology and flexo for the wine and drinks, home and personal care, homeware and food markets.

The Label Makers (F66) and Bristol Labels (C86) similarly deploy flexo and digital printing from their respective bases in Bradford and Bristol. In terms of digital, The Label Makers is a user of Durst’s inkjet digital label printing technology, recently augmented with the addition of a Xeikon CX300 toner press. Bristol Labels meanwhile uses HP Indigo’s LEP technology to achieve success in areas such as craft beverages, although it serves a wide variety of markets with printed labels, from food and wine to vitamins, supplements and CBD.

Also utilising flexo and digital, Abbey Labels (E73) shows off how it produces self-adhesive labels for small start-up companies through to global businesses. The company has not long since bolstered its toner digital printing capability through the addition of a second Xeikon CX300, joining the first in the UK which was installed at the printer’s facility in Suffolk late in 2021.

Another first, not only in the UK but worldwide, has seen Mercian Labels (J62) collaborate with A B Graphic and Cerm to deliver increased workflow automation that has moved ‘lights out manufacturing’ a step nearer to being reality. This combines Screen inkjet digital label printing technology with ABG’s finishing equipment for cost-effective label manufacturing. Also showcased is Mercian’s liner recycling programme.

Alongside its labels expertise, Harkwell (J90) takes the opportunity to showcase its burgeoning digital flexible packaging offer, including a sustainable range, facilitated by recent investments in hardware and people (read page 12 for more).

Digital flexible packaging is also showcased by ProAmpac (N44) – including its ProActive Sustainability option for sustainable flexible packaging products – and CS Labels, which has an established footprint, built on Xeikon’s dry toner digital printing process. This has recently been augmented with the addition of HP Indigo’s LEP process, all of which is showcased by the company under the Asteria Group (N74) banner. CS became part of the group in 2021, launching the European network into the UK. Asteria’s UK footprint has recently been bolstered with the addition of Berkshire Labels to its ranks, an established user of HP’s LEP process alongside analogue technologies. Both businesses are presented on the Astertia stand as the group seeks to reinforce its position as a supplier of labels and packaging, in the UK and across Europe.

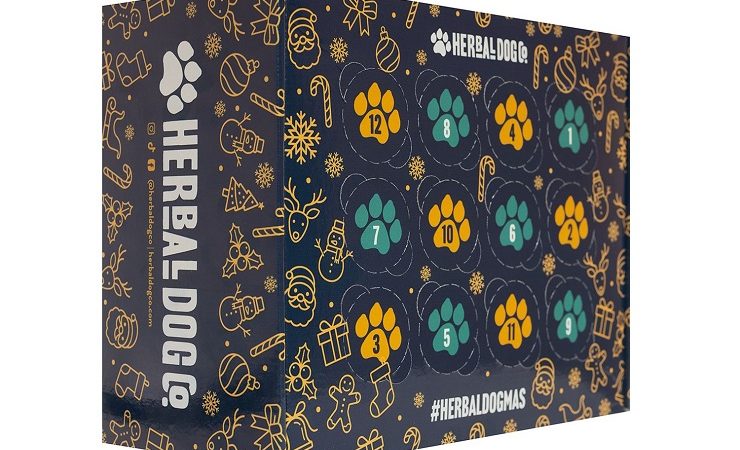

Specialising in the fulfilment of complex projects, fellow packaging manufacturer Alexir (F40) uses digital printing to manufacture short runs of customised cartons. Another to use sheet-fed digital printing technology for the benefit of brands is Durham Box (L46), which uses EFI’s Nozomi C18000 single-pass LED inkjet digital press to turns sheets into high value, customised packaging. A recent example is its work with Herbal Dog Co to create a limited edition luxury dog advent calendar (pictured, top). Examples such as this and others are on show to demonstrate the capabilities of the company’s UV LED inkjet investment.