After the race to achieve high-definition print at top speeds, inkjet technology has now reached a level of sophistication and range to meet all requirements within labels and packaging. By Michal Lodej.

With the race for high print definition at a close, inkjet press manufacturers need to find new areas in which to compete. Luckily the demands from label printers are many, and progressions can be found in a multitude of areas.

Digital Labels & Packaging spoke to Michael Matthews, product manager – DP Colour, Domino Printing Sciences, about the recent trends he has seen in the market. He said: “Recently we have had a lot of discussions around the utilisation of press capacity and ROI of capital equipment. We can boil that down to functionality of speed. Speed is one of the hot topics for us. I think the industry in general saw a rush to get to 1200dpi and to have the highest possible resolution on the market. I think most inkjet press manufacturers have got an offering there, so now it’s all about optimisation and making sure that the crossover between quality and line speed is right for your customer.

“Another trend that we’ve seen is the need for automation, and our efforts are focused on making some of the processes on our presses to be more autonomous and less manual. Giving our customers the ability to press print, leave and trust in the equipment.

The Durst Tau 340 RSC is suitable for variable data printing, specialty packaging, industrial labels, chemical industry applications, food and beverage labels, beauty products, and wine and spirits decoration.

The digital inkjet press operates at 80m/min, printing with a resolution of 1200dpi. The system features up to eight colour stations covering up to 95% of the Pantone colour gamut and using 2-picoliter droplet technology.

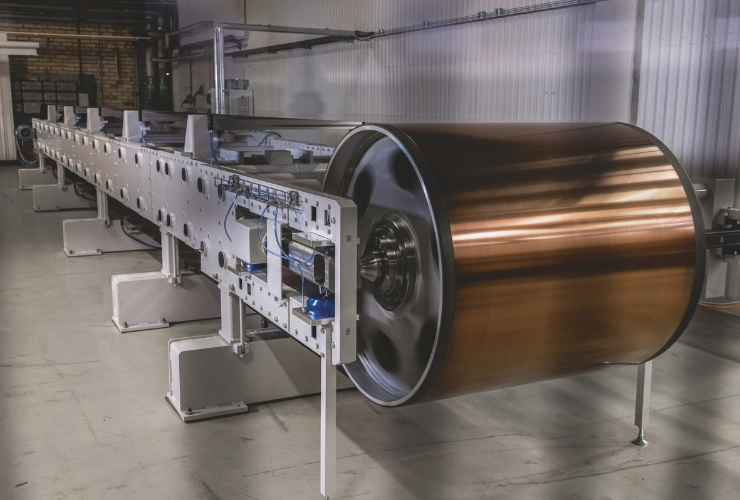

IPCO’s steel belts can be supplied solid or perforated to meet the needs of different substrates

The latest Durst TAU 340 RSC to reach UK shores has found a home at Baker Labels, in Brentwood Essex. Of this investment, Tom Baker, finance and development at Bakers said: “This press will take our inkjet quality to a new level. The team will be excited to get their hands on this one!” The press is the first RSC with LED and the new Hawk Ai scanning system in the UK.

Press manufacturer Screen is also focused on how modern inkjet technology can be streamlined for label production with its Truepress Label range of inkjet presses. The company’s flagship Truepress Label 350UV SAI-S can bring to converters a seven-colour digital engine (CMYK + Orange, Blue, and High-Opacity White), additional embellishing and improved durability with its Digital Primer, all with 60m/min speed.

Consistency is key

It cannot be ignored that every business must work within a budget and so price must come into consideration. For this reason, Gallus is compelling printers to consider the total cost of ownership of a press.

The Gallus One is available in both 340mm and 430mm printing widths, with speeds of up to 70 meters per minute. Gallus has focused on improving the durability, consistency, and maintenance of its inkjet printer, addressing common issues such as frequent downtime and costly repairs. As a result, businesses can now expect more reliable operations and faster delivery times, critical for keeping up with tight production schedules.

According to the company, the Gallus One delivers colour richness, sharpness, and detail, producing prints that meet the highest standards. Its colour accuracy makes it an ideal choice for a wide range of applications and target groups. With the Gallus One’s inkjet technology, brand managers can trust that their products will consistently reflect the true colours of their brand.

Speed freaks

It is inevitable that in conversation about presses, the subject of speed will in raise its perfectly streamlined head. If speed is the next round of competition for the manufacturers of inkjet presses, then Mark Andy are out of the blocks early.

Launched at the Labelexpo Americas 2024, the Mark Andy DSHD HighSpeed 1200 inkjet/flexo hybrid press raises the bar for high-speed, high-quality label production and sets a new benchmark in the industry for performance and efficiency. This latest version of Mark Andy’s well-proven Digital Series HD line is a big step forward in terms of speed and quality making the switch from traditional flexo to hybrid production a whole new calculation.

I know you might be thinking, is it fair to include a hybrid press within this particular discussion, I’ve decided that due to the modularity of the press, i.e. you can have it in any configuration you like, and that at its core is a digital inkjet engine, then it qualifies.

Available in 330mm and 430mm the new HighSpeed 1200 model is capable of 146m/min in up to eight digital colours at 1200dpi, due to the almost unlimited flexibility of specification both before and after the digital print section, decorating and converting inline is possible too.

Raising the production speed of an inkjet engine to 480 ft/min requires powerful software (Mark Andy ProWorx DFE) and liquid cooled control boards integrated into the press chiller to manage the additional thermal load from the data processing power required. One of the key development issues was the decision by Mark Andy to use the two-head system as opposed to native 1200dpi print heads.

Guess who’s back

Dantex Group has relaunched its small-footprint inkjet press the PicoColour. Embodying its original ethos, the press is compact while being designed to provide high-quality printing at an accessible entry level for customers. The modernised PicoColour offers a compelling solution for businesses seeking to enter digital production.

The PicoColour features from the flagship PicoJet using an expanded colour gamut, superwhite, supertext and supertact, with the optional inline finishing. Built entirely in the UK to Zone 1 manufacturing standards, including to CE and UL, the new model achieves print speeds of 50m/min. By prioritising efficiency, service and cost-effectiveness, Dantex refined the design of the PicoColour to print 254mm wide. It now has a fully integrated finishing system that includes shuttle-based die-cutting, lamination, matrix removal, and edge trimming, all while maintaining its small footprint.

Carton options

The demand for digital production of folding cartons is growing and so there are inkjet presses available to target this specific sector. Agfa’s SpeedSet Orca 1060 is one such press, a sheetfed water-based inkjet press. Looking to take the market share away from traditional offset printing presses, the Orca is utilising the benefits of digital to appeal to customers. The SpeedSet Orca 1060 has production speeds of up to 11,000 B1 sheets per hour (150 m/min), 1200dpi resolution an expanded colour gamut featuring CMYK (up to 7 colours optional), and digital primer and varnish.

Belt up

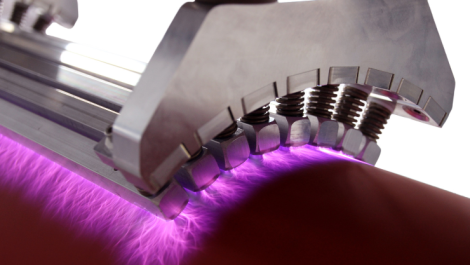

Digital presses based on steel conveyors offer significant advantages in terms of stability compared with traditional plastic belts. In tests carried out by Fraunhofer Institute for Production Technology IPT, the vibration of a steel belt was shown to be as much as six times lower than that of a plastic printing belt.

IPCO’s steel belts can be supplied solid or perforated to meet the needs of different substrates. Thicker substrates like corrugated board, ceramic tiles or board, require a vacuum to keep them fixed and flat during the inkjet printing process. Perforated belts allow the suction forces from the vacuum table to fix the substrate to the belt.

IPCO’s Special Engineering team works with customers on a project basis to ensure that the end solution meets the specific design constraints of the system and that performance and production benefits are optimised for a specific process.