Implementing both digital and flexo production to win the Digital Labels & Packaging Award for Excellence with Hybrid Printing, Labelnet brought together all the right components for success.

When Labelnet’s Rob Lorkins collected the Digital Labels & Packaging Award for ‘Excellence with Hybrid Printing’ it marked a significant milestone for the UK-based converter. But behind the accolade lies a fascinating story of creative collaboration, technical innovation, and the kind of problem-solving that defines modern label production.

The project’s genesis wasn’t a client brief demanding a peel-and reveal label. Rather, it emerged from within Labelnet’s own studio. Matt, studio supervisor, who regularly reviews incoming artwork, had long been captivated by Hackney Church Brewery’s distinctive branding approach.

Much of what they supply to us draws on church and religious elements,” explained Rob Lorkins, Labelnet managing director. “Matt was particularly keen to incorporate that theme and create a stained glass window effect using a peel-and-reveal label.”

The brewery had different initial ideas, wanting a production job rather than an experimental piece. The team took one of Hackney Church’s newer designs—the Noah’s Ark concept—and applied the peel-and-reveal concept to it. The original artwork had no such interactive element; that was entirely Labelnet’s innovation.

From their perspective, it wasn’t intended as a peel-and-reveal,” Mr Lorkins noted, “but from our standpoint it always was, as we were developing that concept and felt it would be an ideal fit.”

Testing, testing

The foundation for this achievement was laid six years ago when Labelnet invested in the Domino N610i digital label press. The machine has been transformative, opening doors to projects that simply weren’t feasible with their previous equipment.

We’re always interested in producing work that’s distinctive,” he says. “Many of the capabilities of that machine have enabled us to test various techniques that we’ve not been able to achieve previously.”

Peel-and-reveal isn’t a standard offering at Labelnet, and none of their equipment is specifically configured for regular production of such labels. However, by combining their digital and flexo capabilities, they can achieve remarkable results. The challenge is that complex designs, particularly those with multiple colours or tight registration requirements, can’t always be completed in a single pass on flexo alone.

“We’ve got to try and utilise machines within our business to achieve what we want to.” Mr Lorkins explained. This philosophy of combining processes has become central to Labelnet’s approach to innovation.

The technical challenge

The ‘Noah Knows Best’ label required a sophisticated multi-stage production process. The project was produced on two layers of white polypropylene, starting with the base image on the Domino N610i. This first layer featured the photographic images of the animals—a design element that Mr Lorkins felt would lose quality if attempted on flexo.

We’ve never really had a viable option to reproduce that type of photographic image on flexo because the quality would have been inadequate.”

Popularity of peel-and-reveal labels is growing

After printing the first layer, a blank second web was laminated on top. The team then moved to their Edale FL3 for the next stage, printing on the adhesive to create the door image, applying adhesive, and adding release lacquer. Finally, the top layer was printed on the Domino, creating the complete label structure.

Registration posed the most significant technical hurdle. Bringing together two materials while ensuring the base image aligned perfectly with the front print required both technical precision and operator skill.

We apply registration marks, but some adjustment needs to be done visually to ensure correct placement,” Mr Lorkins explained. “That can only really be achieved by peeling back and examining the material.”

The right touch

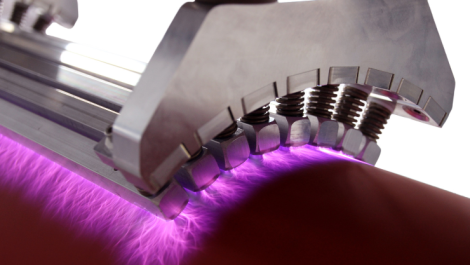

The finishing touch came from an AB Graphics’ Digicon, which applied a heavily textured varnish—a detail that has become almost standard in the craft brewery sector.

The volume of texture varnish we use these days is remarkable,” Mr Lorkins said. “The breweries appreciate it, so we continue to offer it.”

But achieving that perfect tactile finish hasn’t been straightforward. Labelnet spent five or six years continuously developing their handling of texture varnishes, testing products from different ink suppliers and refining their application methods.

When we first began using that, we struggled considerably,” Mr Lorkins recalls. “We were running at very slow speeds. The operators had to constantly agitate it to prevent the particles settling. It was damaging doctor blades on the machine and spilling everywhere.”

Now offering both “heavy” and “light” texture options—what some converters call sandpaper or rough touch—Labelnet has mastered the process. They’ve found their preferred formulation and can now run at decent speeds, though it remains a production consideration.

The educational gap

When asked why more brands don’t embrace innovative label constructions like peel-and-reveal, Mr Lorkins points to a fundamental knowledge gap—particularly in the craft brewery sector that Labelnet serves extensively.

“I think it’s largely an educational matter. How much do they actually understand what’s achievable?” he asks. “It was our suggestion to incorporate the peel-and-reveal element. Unless a label printer proposes it, perhaps most clients simply aren’t aware of the possibilities.”

The challenge for Labelnet is timing these conversations appropriately. While they produce marketing materials and samples showcasing their capabilities, knowing when to suggest enhanced solutions requires judgement.

It represents an additional value opportunity for us,” Mr Lorkins explained. “If we attempted that with every design submission, clients would become frustrated. It depends on your relationship with customers—understanding who to approach and when.”

Time pressures also play a role. The quick turnarounds that digital printing enables become eroded away when multiple processes are involved. In a market where breweries often request labels with just three days’ notice, there’s simply no opportunity to propose more elaborate solutions.

Craig Clawson, sales manager at Domino, expresses pride in Labelnet’s achievement, “Rob showed me the label before the awards, and I was really impressed. It’s a fantastic label, and the fact that it used a few processes, using our press for one layer and then re-registering for another layer, shows the flexibility of the system.”

The judges’ comments certainly validate the technical accomplishment: “The initial impact of the label is excellent and eye catching. This is further enhanced by the inner label peel-off door to reveal the print underneath, with the added detail of the double-sided print of the door peel to create the full ensemble.”

For Mr Lorkins, the award represents validation of Labelnet’s approach to innovation. “We are incredibly proud and honoured to have won this award in a very competitive field,” he reflected. “Winning in this category is a huge credit to the ingenuity and skill within our workforce, as well as the versatility, consistency and quality that Domino offers.”

The success of ‘Noah Knows Best’ demonstrates how mid-sized converters can compete through creativity and technical versatility rather than sheer volume. By combining digital’s flexibility and quality with flexo’s specialised capabilities, Labelnet has carved out a distinctive position in the market.

“These production difficulties—yes, there were some, but they weren’t significant,” Mr Lorkins concluded. “They certainly wouldn’t prevent us from producing similar work in future.”

In an industry where differentiation is increasingly challenging, the ‘Noah Knows Best’ label proves that creative problem-solving and technical capability remain powerful competitive advantages. Labelnet has shown what can be accomplished when you have earnt your customers’ trust and can show them a more innovative path.