Xaar has introduced an enhanced fluid development and optimisation process designed to help manufacturers and OEMs bring inkjet systems to market faster, while reducing costs and development risk.

The Cambridge-based printhead manufacturer’s new flexible approach gives customers three pathways for fluid development, offering options to use Xaar’s pre-approved fluids, adapt their own formulations with existing waveforms, or create bespoke solutions with full technical support.

Xaar ‘s approach gives customers three development pathways

By using Xaar’s experience in jetting challenging fluids, such as those with high viscosity or particle loading, customers can validate performance early in the process and minimise upfront investment. The company says this approach enables faster R&D cycles and supports the development of high-performance, innovative inkjet applications.

In one example, Inkatronic used the new process to validate its wood panel printing project in less than a month. “Xaar’s support was outstanding,” said Mikael Boedler, head of new business development at Inkatronic. “The pre-developed waveforms significantly reduced our testing time, saving us months of work.”

By combining Nazdar’s pre-approved water-based fluids with Xaar’s in-house print trials, Inkatronic was able to produce validated samples quickly and with minimal complexity.

Graham Tweedale, Xaar’s COO, said: “We understand how crucial speed, performance and cost are when developing new inkjet systems. Our new process gives customers the flexibility and tools they need to innovate faster and reduce risk, whilst remaining in control.”

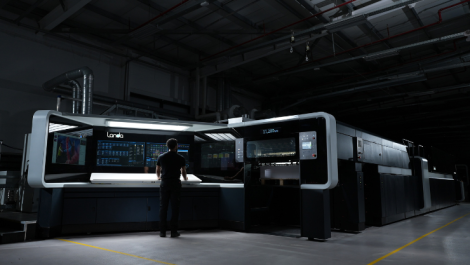

Xaar’s latest development reflects its continued focus on collaboration and innovation across industrial inkjet markets, including graphics, packaging, décor, textiles and advanced manufacturing.