Sustainability has proven to be an increasingly influential driver for flexible packaging production. Various brands have been working to increase renewable material usage, minimise C02 emissions, improve End-of-Life (EOL) recyclability, and reduce the overall amount of virgin plastic packaging for their products. This new demand is changing how packaging is perceived by both the industry and the typical consumer, driving the push for new, more environmentally friendly and sustainable materials like paper for flexible packaging.

Responsive to these consumer preferences and more stringent regulations, many leading brands are committing to more sustainable packaging and reducing their reliance on virgin plastic, with some brands setting ambitious goals to cut virgin plastic use by up to half by 2025 and make their entire packaging portfolio either recyclable, re-usable or compostable. Some brands are extending these efforts even further, aiming to minimise plastic consumption further or ensure all packaging is recyclable by 2030.

While consumers and the industry are concerned with improving sustainability, the primary purpose of packaging is still to offer sufficient product protection throughout the supply chain (manufacturing, transport, shelf life), the speed of the shift to paper packaging depends on the industry’s ability to introduce paper-based solutions that meets the same performance profile and product protection requirements of the incumbent plastic packaging that intends to replace, but at an affordable cost.

Innovations in sustainability practices are making paper an increasingly versatile and modular solution for flexible packaging applications, and the amount of traditional plastic multi-layered laminated structures that can now be viably replaced by paper-based packaging are increasingly diverse and present ample opportunities for growth.

For various applications, improvements in barrier coatings are vital to protecting against oxygen transmission (OTR), grease, mineral oil, aromas, and moisture (WVTR) as required. Combining these new structures modularly based on protection requirements allows flexible paper packaging to better cater to the diverse shelf life demands of products.

Printing is one major step throughout package converting, where selecting the right innovative solution can result in considerable sustainability improvements throughout the entire supply chain.

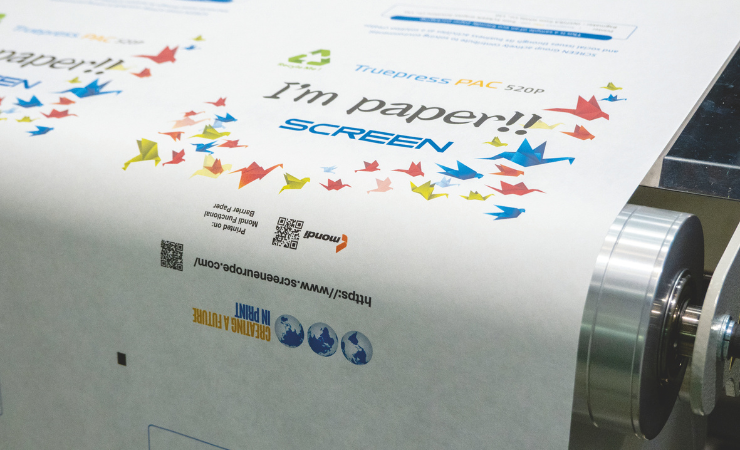

During the ramp up market development of paper packaging, digital inkjet printing is the ideal printing method to accelerate its mass market adoption. When compared to traditional analogue printing processes like flexography and rotogravure, inkjet digital printing offers a significantly lower environmental impact while being compatible with a variety of paper substrates—especially for personalised or short-run packaging jobs that are vital early in the lifecycle of a new packaging design to help consumers embrace changes in familiar products.

Reduced Energy Consumption

Compared to traditional printing methods, inkjet printing consumes less energy and generates minimal waste without the need for plates or cylinders. This leads to lower carbon emissions and reduced waste disposal, contributing to an eco-friendlier production process. The Truepress PAC 520P uses less energy compared to traditional analogue printing processes, and its robust design prevents errors and malfunctions that would require additional energy expenditure with reprints.

Water-Based Inks

The water-based inks used by this press reduce the exposure of printing operators to harmful volatile organic compounds (VOCs) and are food-compliant, meeting the Swiss Ordinance, Nestlé Guidance, and EuPIA regulations, while having a drastically lower environmental impact compared to solvent based inks used in traditional processes. The thoroughly formulated and high-pigment loads of these inks also benefit from consuming less ink to perform similar orders and simplifying maintenance.

Minimal Waste

Without the need to create new printing plates or engraving cylinders before each production run, digital printing further reduces energy consumption and the use of environmentally harmful solvents and cleaning materials.

Additionally, digital presses like the Truepress PAC 520P have minimum ramp-up or ramp-down requirements before beginning production requiring even less energy, inks, and substrates with the additional benefits of improved print on-demand capabilities reducing the overproduction and inventory requirements.

Print-on-Demand and Reduced Overproduction

Inkjet digital printing excels in print-on-demand capabilities, allowing brand owners and packaging converters to produce only the required quantity. This significantly reduces the risk of overproduction, which often leads to waste and unnecessary CO2 emissions associated with disposal. By ensuring that only the necessary packaging is produced, the on-demand model minimises both waste and emissions.

By avoiding overproduction and the generation of obsolete packaging, less packaging ends up as waste, leading to a lower carbon footprint during the disposal and improved cost-effectiveness.

This article is an advertorial; the featured company created the wording and paid for its placement. It has been checked by Whitmar Publications to ensure that it meets our editorial standards.