Midlands-based cardboard engineering specialist N Smith & Co has installed a fully automated Agfa Onset X3 HS, the first UK installation of such a print engine.

N Smith & Co was established in the centre of Birmingham in the UK towards the very start of the 20th Century. It initially manufactured solid board boxes for components in the automotive industry. This continued with carton solid board boxes that housed industrial nails and hinges, etc throughout the 1960s, 1970s and 1980s. Corrugated box production was then added to the business. Conventional boxes only were made until the late 1990s, when silk screen and litho print was introduced for products provided by external suppliers. In the early 2000s, N Smith & CO bought a screen print business and started in-house print production on the boxes it was manufacturing. In 2013, the first digital press was added to the company’s production mix. Further digital presses have been added since then.

Fast-forward a decade and the ‘sizeable’ investment in the Agfa Onset X3 HS has been made to support the business and its growth aspirations. Onset X3 HS enables single-cycle printing at up to up to 1450sqm per hour. Robotic technology is used to automate various production and material handling requirements. N Smith & Co chose to upgrade and add full automation, dual robot and three-quarters laytable to its purchase, ‘to significantly boost productivity’. This means a variety of sheet sizes can be pre-positioned during the printing process.

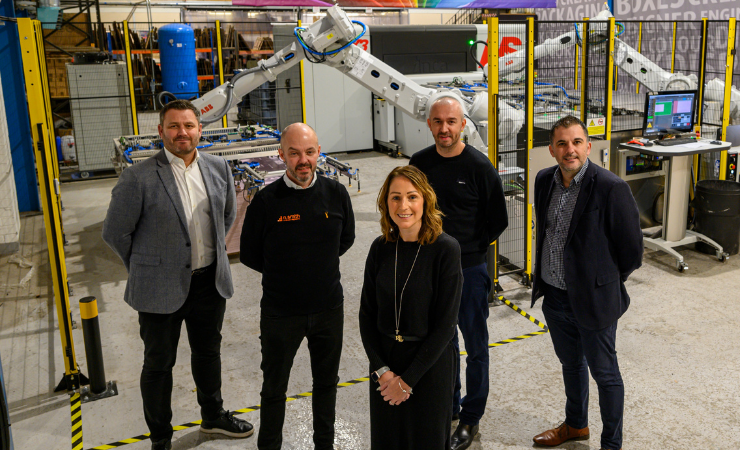

The Agfa Onset X3 HS was ordered by N Smith & Co in May last year and delivered in September. As noted by company managing director Nigel Reynolds, this allowed the company to successfully work through a surge in business, as well as deal with a lengthy breakdown of an existing machine.

‘Since 2013, we have purchased five digital print machines including two Incas, an Arizona and an HP Scitex. We learnt a lot during those purchases and this time had very specific objectives. We wanted to go to the maximum spec with this new machine to reduce the strain on our existing printers as well as to satisfy growth with existing customers. We also wanted it to take the business to the next level to allow us to look for new opportunities and also move into new markets.

‘The Onset has delivered some really good quality work, even better than I was expecting. We initially calculated that it would achieve the same level of workflow as our existing machines but on a whole shift less, whilst this is an accurate calculation in reality this hasn’t happened as yet due to an unexpected influx of business.’

N Smith & Co operations director Gary Hogg said, ‘We started using the machine immediately as we had an unexpected amount of business along with a lengthy breakdown on an existing machine, so the operatives had to get up to speed quickly. They find the automation excellent. It’s difficult to quantify how much time you lose by someone manually feeding a machine whereas with complete automation you eliminate this. Manually feeding cardboard onto a printing machine can get very intensive, some of the boards are 1.5 x 2.8m and the operative must lift four or five boards at a time, so automation is a lot better for the operator too.’