Kongsberg Precision Cutting Systems (PCS) has developed Ultimate, a new digital cutting platform aimed at the corrugated market with a feature set claimed to achieve ‘unprecedented levels of productivity, precision and safety’.

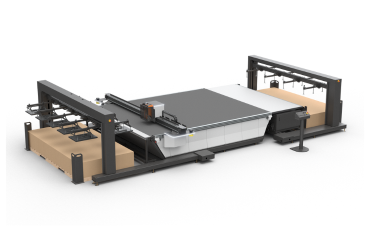

The Kongsberg Ultimate can be configured with automatic feeding and stacking

Ultimate is available in four models – 24, 44, 64 ,66 – with respective work areas of 1680 x 3200mm, 2210 x 3200mm, 3210 x 3200mm and 3210 x 4800mm (multizone work areas of 1680 x 1450mm, 2210 x 1450mm, 3210 x 1600mm and 3210 x 2210mm). Without conveyor feed, the models’ respective maximum material sizes are 1780 x 3920mm, 2310 x 3920mm, 3330 x 3920mm and 3330 x 5520mm. The maximum material sizes with conveyor feed is 1680, 2210, 3210mm and 3210mm. All four models can process sheets with a maximum thickness of 30mm. All have a maximum linear speed of 167.5m/min. A maximum acceleration rate of 2.74G can be achieved with the Ultimate 24 model, although this drops to 2.65G (44), and 2.5G (64 and 66 models). Automatic feeding and stacking configurations are available also to further enhance the machine’s productivity. The full specifications can be found here.

Kongsberg Ultimate has been engineered to directly address the ‘unique challenges’ faced by corrugated converters involved in continuous high volume multi-batch production. This is centred around the follow six core design values:

- Productivity, delivered by a new drive and beam design;

- Precision, with a custom carbon fibre beam providing ‘unparalleled’ stiffness and consistently applying a 50kg downforce; the tool head camera ensures every cut is aligned;

- Safety, thanks to the Kongsberg Smartzone safety system that is a proximity-driven dual-zone option; and the use of LED lighting to ensure the machine status is clear;

- Uptime, achieved by way of self-diagnostics and remote operator alerts;

- User experience, enhanced with an IPC 3.0 interface with touchscreen; and

- Sustainability, through the greater use of recycled, readily recycled and other materials with less environmental impact.

Kongsberg PCS president and CEO Stuart Fox said, ‘Engineered with our deep understanding of corrugated and display converters’ needs for precision, the Kongsberg Ultimate promises to redefine standards and usher in a new era of productivity and innovation, delivering a fast return on investment for convertors of corrugated board.

‘Enhancing operations and providing a significant competitive advantage, the platform sets a new industry benchmark and is set to drive the future of corrugated production for years to come. With corrugated converters around the world under increasing pressure to produce better, faster, safer and more efficiently to meet the demands of the global market, we have underlined our commitment to deliver a solution that has been engineered for precision and built for productivity.’

‘The platform sets a new industry benchmark and is set to drive the future of corrugated production for years to come.’ – Stuart Fox, Kongsberg PCS president and CEO