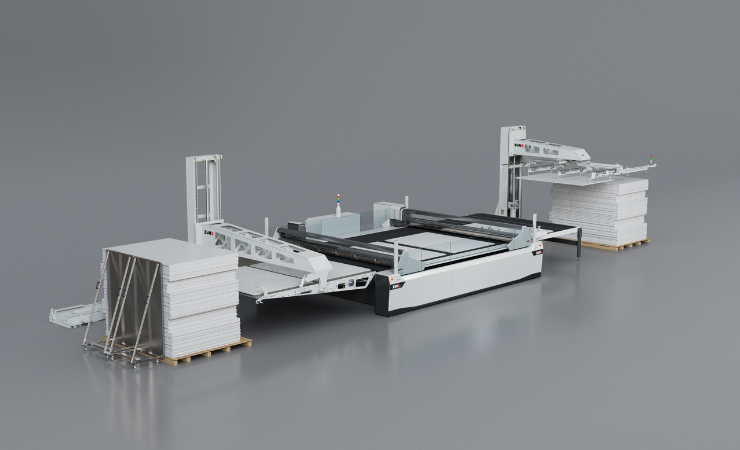

Zünd, manufacturer of digital cutting technology, is expanding its machine portfolio with the new Q-Line with BHS180, a fully automated pallet-to-pallet loading, cutting and stacking system.

The Q-Line with BHS180 complements Zünd’s current offering to provide efficient industrial-level ‘pallet-to-pallet’ production via an integrated system. It is specifically intended for the demands of highly automated, industrial finishing of printed boards for displays and packaging. The individual components – board feeder with Undercam, the new generation Q-Line cutter and the off-load unit – are coordinated to provide high levels of productivity.

The Q-Line with BHS180 comes with the latest generation of modules and tools. Automo L provides a creasing force of up to 50kg, while Automo E increases the speed at which the tools in use are lowered and lifted. Each beam of the cutting table has a total of four modules: two Automo E modules, one Automo L, and one fixed Incam sensor module to capture registration marks, QR codes and material edges.

Unito is used with centred and off-centred drag knives and is suitable for processing materials up to 5mm thick. Elosto is available in two different variations for cutting operations requiring electric motor-driven oscillation.

Q-Line cutters are supplied as standard with an automatic tool-changing system. The Tomac Tool Management Client is designed to offer easy and automated processes, digitally linking the tools with presets, which saves time in setup and tool changes.

The automatic material transport from pallet to pallet is designed to maximise productivity. The system captures information stored for each job using QR codes as uses this as the basis for the workflow. The Undercam integrated in the board feeder detects the location of the image printed on the board, identifies and compensates for distortions in the print, and matches the cut to the print. With every scan, the software adjusts the cut paths to the printed image, on the fly. During the feeding process, sensors capture the edges of the material, and the board is correctly aligned. If the board is not within tolerance, the board feeder realigns the board so that it can be fed onto the cutter, allowing even imperfectly stacked materials to be processed.