S-One Labels & Packaging (S-OneLP) is introducing its FlexPaper Barrier flexible packaging paper portfolio into the EMEA region, a paper-based coated structure specifically designed for use with HP Indigo digital presses.

FlexPaper Barrier is a prelaminated product, manufactured as a multilayer structure consisting of paper and plastic. The paper component is FSC certified and the polyethylene/EVOH COEX sealant layer prevents leaking and keeps contents fresh, it is noted, whilst grease, oil, water vapour and oxygen barrier properties further help extend the shelf life of packaged goods. Puncture resistant and heat sealable, FlexPaper Barrier is a white substrate that eliminates need for white ink – lowering ink costs and allowing faster print speeds – and offers high opacity.

It is available as two options, application dependent: S-OneLP FlexPaper Barrier Snack Web, available at 60gsm/65µm on a six-inch core; and S-OneLP FlexPaper Barrier Plus Pouch Web, coming in at 140gsm/145µm on a six-inch core.

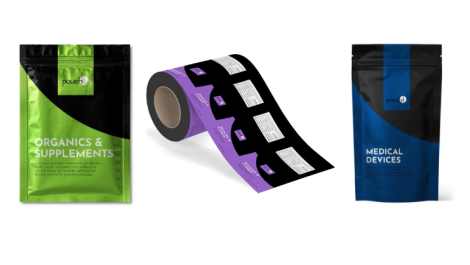

Whilst it is the first paper-based coated structure in the S-OneLP EMEA line specifically designed for HP Indigo’s LEP process and the company’s digital presses, FlexPaper Barrier papers can also be used with a range of systems from flexo press manufacturers. The application range for FlexPaper Barrier includes stand-up pouches, flat pouches, pillow pouches, sachets, and flow wraps. HP Indigo printable products are specified as suitable for chilled and frozen food, pharmaceuticals, cosmetics, and other perishable products.

For converters, S-OneLP stated that FlexPaper Barrier meets demand from those who, ‘want to save money, increase profits, print faster and have the ability to place low minimum orders.’

Gerard Geurtz, responsible for business development and technical sales at S-OneLP, commented, ‘We are pleased to expand our prelaminated product portfolio offering in EMEA that meets the needs of converters wanting to discover new revenue opportunities.

‘Another added benefit is we do not turn away small orders for shorter lead times and quick production.’