Germany-based Thimm Group is to install an HP PageWide T1195i digital press, as the business seeks to further its digitalisation strategy.

Thimm Group is a provider of products for packaging and distribution, such as corrugated cardboard transportation and sales packaging, high-quality promotional displays and print products. Founded in 1949, the family business currently has more than 2500 employees at 13 sites in Germany, France, Poland, Romania and the Czech Republic. These are split across group companies Thimm pack’n’display, Top Packaging, Christiansen Print and Cartonara.

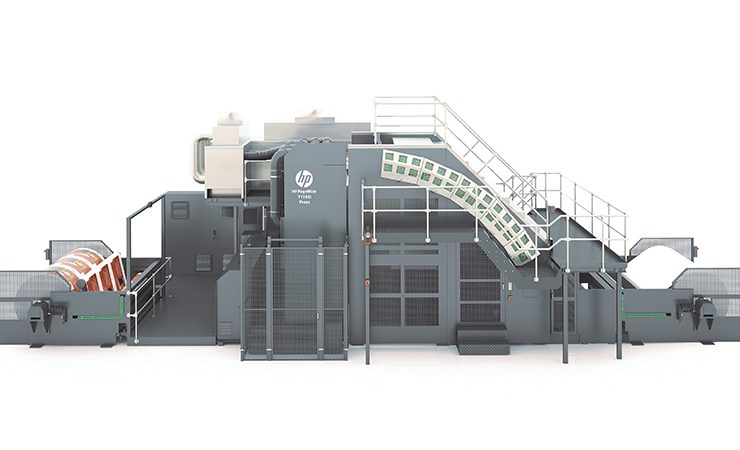

This latest investment is to be the group’s second digital web press from HP, following on from the commissioning of a PageWide T1100S at the Christiansen Print site in Ilsenburg, Germany in 2017. Whilst Thimm claimed to have already reduced lead times by 75% and minimum order quantities by 90%, the new six-colour press builds on the previous model and offers faster speeds and more production capacity along with an operating width of 2.8m. It is scheduled to be commissioned at the Thimm pack’n’display site in Alzey, also in Germany, during the first quarter of 2024. The digital preprint press be positioned directly next to an existing corrugator, further reducing lead times by up to two days as there will no longer be any need to move printed rolls. Together with the necessary peripheral works, the total investment for the new 50m-long printing press is around €20 million.

Thimm Group has an active digitalisation strategy, with the objective to, ‘drive forward the digitalisation of the entire supply chain, including beyond the packaging industry.’

‘To do this,’ explained Kornelius Thimm, Thimm Group CEO, ‘we need relevant data as well as digital and intelligently networked processes – from the printed paper roll through packaging production to retail and end consumers. Printed packaging acts as an information carrier because it is the only item that runs through the entire supply chain. At the heart of this vision is digital printing, which enables continuous codes to be printed in infinite numbers on the paper rolls. These codes provide relevant information at various points in the supply chain. For example, they control any further processing required on the paper at the machines in the packaging plant, provide data on the sale of the product or provide further information for end consumers as a QR code.

‘Our digitalisation vision is the “Internet of Packs”, i.e. the networking of machines or objects in packaging management analogous to the Internet of Things. Each package has a unique code and can therefore be traced through the entire supply chain. The new digital printing system will bring us one decisive step closer to our vision.’

Mr Thimm continued, ‘In view of the increasing requirements of our customers, we at Thimm have set ourselves big goals: no lead times for the production of packaging and displays, no minimum order quantities (MOQ), no additional costs in the supply chain and all within a sustainable manufacturing process. We have already achieved a great deal with our first digital printing system in Ilsenburg.’

Sir,

Could send us more details, datasheet for this machine: HP PageWide T1195i digital press.

and samples of prices as a start,