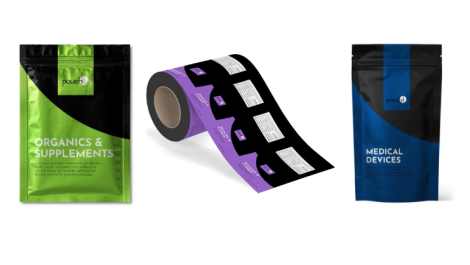

ePac Flexible Packaging is expanding its offering to include long run orders for brands of all sizes, while continuing to serve its SMB core customer base.

Launched in 2016, ePac has built itself a successful business model serving small and medium-sized brands with digitally printed flexible packaging. Such customers had previously been underserved by traditional flexible packaging supply chains owing largely to costs and volumes.

These impact the crossover point, which is the point at which the run length of a job makes it more cost effective to use conventional versus digital printing. Other factors also come into play, such as lead times, plates, freight and inventory obsolescence costs. Combined, these determine when a job is best run digitally. Increasing this crossover point is where the ePac has been focused.

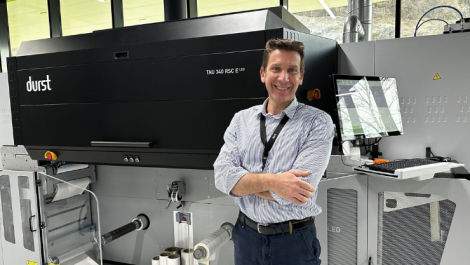

The company has been steadily building its infrastructure to increase the run length of jobs that are cost effectively produced on its fleet of HP Indigo digital presses located around the world, which is soon to nearly double to more than 100 presses globally. As well as printing capacity, ePac has developed its own job management system to move or split longer run jobs to the locations best suited for a particular job, while maintaining lead times of 5-10 business days for rollstock and 10-15 days for finished pouches and maintaining colour consistency among all devices.

According to Parag Patel, president of global services at ePac, ‘We have tremendous relationships with our suppliers, all of whom have helped us expand globally, add capacity, and be creative in assisting us to find ways to increase our addressable market.’