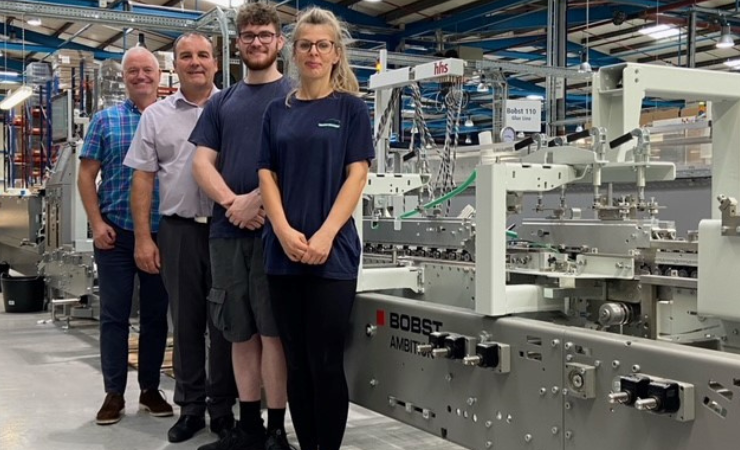

Chester Medical Solutions has furthered its partnership with Bobst after installing a new folder gluer at its facility in Deeside, North Wales.

The pharmaceutical packaging manufacturer and contract packer manufactures cartons and patient leaflets at the 60,000sqft facility for the pharmaceutical, medical device and nutrition markets. It operates both conventional and digital print technologies.

Ronnie Delamar, operations manager at the Deeside site, said, ‘As a business we must adapt to customers’ changing needs. Currently, we are seeing customers ordering smaller volumes per job but more frequently. This requires us to think differently about our approach to manufacturing cartons to be as efficient as possible. Our new folder gluer complements our existing conventional and digital printing capabilities, while at the same time enabling us to respond to requests for more complex packaging formats, for example internal fitments, by increasing our capacity across production lines.’

The new folder gluer, installed in April, can handle most carton styles and offers ‘excellent’ consistency in production and quality. The machine is modular and flexible to meet changing market needs and offers a simple set-up and quick job changeovers. It brings the total number of Bobst machines at the site to four, including an Expertfold 110 folder gluer, Novacut 106 die-cutter and Evoline SP 102 die-cutter.

Tammy Williams, sales director at Chester Medical Solutions, added, ‘As we continue to grow, investing in our business and site as a whole is a priority so that we can continue to deliver quality products in the quickest time possible.’

Lee Alton, area sales manager, Bobst UK & Ireland, said, ‘We have worked with the team at Chester Medical for several years. Our focus has always been to support its growth strategy and understand the business as well as we do our own, so that it has the right machines in place to address any production challenges that come up.

‘We are delighted that we have been able to deliver once again and provide a machine that meets the company’s requirements and look forward to continuing our strong partnership in years to come.’