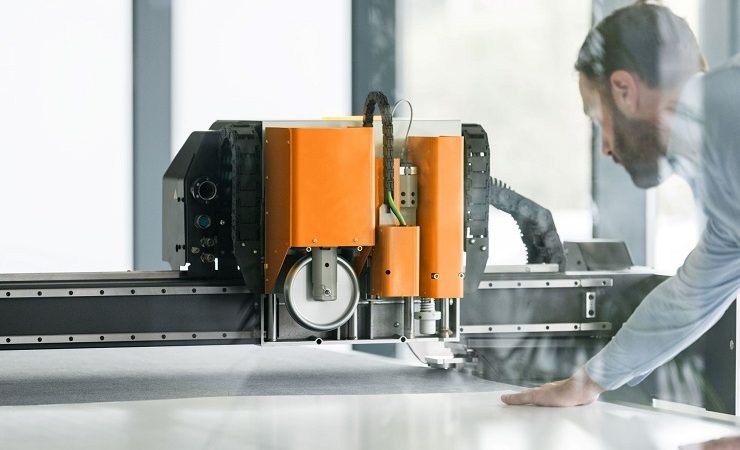

Kongsberg Precision Cutting Systems (PCS) has formed a number of partnerships to showcase its digital cutting technologies to customers at demo centres across Europe, the Middle East and Africa.

This has seen the company work with several of its distribution partners install Kongsberg cutting tables and tooling combinations in their demo centres across the EMEA region. Specifically, this sees Kongsberg cutting systems, tools, software and automation products now displayed and demonstrated to customers at Dynagraph in Dubai (UAE), KTA in Helsinki (Finland), Lexplast in Tallinn (Estonia), Lidya Group in Istanbul (Turkey), Getter Group in Tel Aviv (Israel), and at two Graphic Supply World demo centres in Cape Town and Johannesburg (South Africa).

The move is part of the company’s commitment to better serve its clients and provide a more localised service where possible. In addition, given the recent global pandemic and worldwide shift towards reducing work-related travel, these demo centres are viewed as an important investment.

Judd Perring, Kongsberg PCS EMEA territory sales manager, ‘We’ve all experienced first-hand how the Covid outbreak affected the way that many businesses are operating, not least the significant impact the situation has had on business travel. There’s every chance that the way the industry has adapted to these conditions will influence and transform the way people work for many years to come. With that in mind, Kongsberg PCS and our partners recognised the need for local demonstration facilities across EMEA, and we have worked with our distribution partners to open several new locations, in addition to our existing locations in the UK, Ireland, Poland, Spain, Denmark, Italy and at the Kongsberg headquarters in Gent, Belgium.’

Kongsberg PCS president Stuart Fox added, ‘Kongsberg cutting solutions are renowned for delivering the most robust and reliable digital cutting solutions to packaging, signage and display markets worldwide. We want to ensure that customers are able to witness the power and performance of our range without having the expense, inconvenience and environmental impact of travelling half-way around the world to do so.’