McGowans Digital Print has taken the next step in its digital journey with installation of the first Highcon Beam 2 digital cutting and creasing system in Ireland.

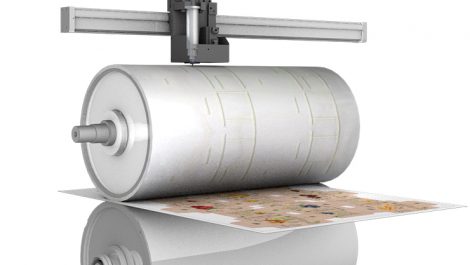

The Highcon Beam 2 has been installed as part of an end-to-end digital print and packaging workflow for folding carton and micro flute corrugated packaging jobs. This includes a Landa S10 press.

Installed at McGowans’ Dublin facility, the Highcon technology is enabling the company to meet increasingly tight deadlines for short run jobs, with less set-up time and waste. The new Highcon investment will also support new business from McGowans’ all-new on-demand e-commerce packaging platform, BoxJob.com, which officially launches in May.

In combination with the Landa press, the company expects to utilise this technology to expand into new and profitable packaging jobs, and realise a 30% increase in revenue within three months. Both bits of technology were installed las year, with the Highcon Beam 2 fully operational for six months, supporting jobs from standard boxes, to sophisticated packaging and displays.

Mal McGowan, founder and CEO at McGowans, said, ‘What the Highcon brings to the table is real digital finishing. It’s not only cutting, it is creasing and stripping too. It does so much more than a traditional analogue solution. The introduction of a digital finishing process here has dramatically streamlined our production workflow for increased efficiencies. And crucially, having the Landa S10, Nozomi and HP Indigo working together with the Highcon Beam 2 also means that we can offer customers a ‘virtual house’ for all their packaging or display needs. Literally, customers can now make changes to their packaging designs on the fly, produce a smaller batch or simply run a limited seasonal promotion – but without the expensive or waste of unwanted stock, that also has to be stored in expensive real estate. Cool floor graphics and display applications are also reaping the benefits of digital cutting and creasing including improved production times for point-of-sale displays.’

The Highcon Beam 2 also contributes to the company’s sustainability goals. It does this by eliminating the wood, metal and rubber components needed to produce traditional dies, as well as the associated logistics and warehouse costs needed to store them. In addition, it also contributes to a reduction in traditional print volumes and its associated waste, by powering new digital short to medium run jobs.

Mr McGowan added, ‘It is the speed, flexibility and on-demand capabilities of the Beam 2 that sell this machine. The amount of work you can do with the Highcon is beyond good. Of course, large brands can rely on us for their short-run packaging requirements, but with the introduction of our new website BoxJob.com, we can now also support low volume business – perhaps a small business working online from home. We are excited to see what new doors the Highcon Beam 2 can open for us.

‘With the increasing demand for more complex and shorter-run jobs, the Highcon Beam 2 is the perfect solution for McGowan’s – improving its digital manufacturing capabilities, increasing capacity, improving lead times and opening the e-commerce market. This is a booming segment right now.’