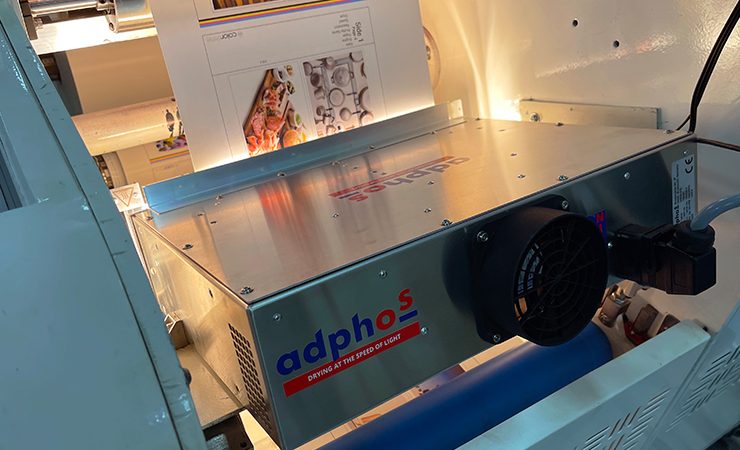

Adphos has developed NIR30-375-E, a dryer specifically tailored to meet the needs of Colordyne’s ChromaPlex LT water-based inkjet digital print engine.

Colordyne engaged Adphos to develop a 13in-wide, dual emitter dryer using the company’s patented aNIR technology. The goal was to expand the existing partnership between the companies by working together on a system dedicated to Colordyne’s ChromaPlex LT engine, which itself is powered by Memjet’s DuraFlex printhead technology.

This new dryer allows end users to print on a greater variety of substrates using Colordyne’s full-colour, water-based pigment inkjet technology. The NIR30-375-E was designed with the Chromaplex LT’s ink chemistry, print speeds and potential applications in mind. This tailored approach allows for high productivity at an affordable price point.

Designed and manufactured by Adphos, NIR30-375-E will be available through Colordyne and its strategic integration partners (SIPs), as of 27 September, 2021. Colordyne will also offer this technology directly to end users of its 2800 Series AP – Retrofit.

John Urban, director of engineering at Colordyne, said, ‘When taking on this project, we wanted to ensure that we would meet the performance needs of the end user, whilst also delivering a cost-effective dryer for our SIPs. We were already working with Adphos on drying technology for our ChromaPlex AP engine and knew it could meet these requirements.

‘Adphos has been a great partner to Colordyne, and we know they will continue to support us and our SIPs as we bring the NIR30-375-E dryer to market.’

John Palazzolo, director of marketing and sales at Adphos North America, added, ‘Together we can deliver a compact, high-performance inkjet printing and drying technology to partners in markets like labels and packaging. We look forward to working with and supporting Colordyne’s SIPs during their integration process.’