Arrow Systems and Sihl have entered into a partnership to allow printers to produce digitally printed flexible packaging inline in a single production step, up to 324mm-wide with water-based, pigment inkjet.

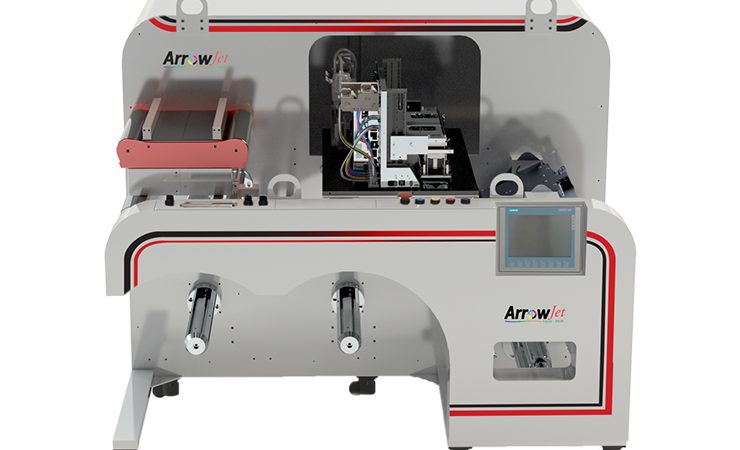

This sees the ArrowJet Aqua 330R printer coupled with Artysio flexible packaging materials. ArrowJet Aqua 330R is a 330mm-wide water-based pigment inkjet press that can run at speeds up to 45m/min with a resolution up to 1600 x 1600dpi. Sihl’s Artysio films, in combination with DuraFlex pigment ink, are compliant with numerous food safety regulations. For example, DuraFlex PZ ink for food packaging is formulated using components listed on the Swiss Ordinance (RS 817.023.21) and compliant with the Nestle Guidance Note on Packaging Inks, dated October 2018.

Shaan Patel, business development manager at Arrow Systems, said, ‘We feel that the flexible packaging space is one that has enormous growth potential. We understand that the majority of customers in this space are currently outsourcing their flexible packaging needs because, in the past it has been too costly or difficult to produce them in-house. We believe that the combination of the Sihl materials with our pigment inkjet press will allow more customers to begin producing their own short-run flexible packaging.’

Ronny Kunze, responsible for business development at Sihl Group, said, ‘Partnering with Arrow has been great. Its team understands the benefits of on-demand printing and has been quick to adapt with any changes that we have thrown their way. We are looking forward to bringing our combined product to market worldwide over the next few months.’